-

All Products

-

Trapezoid Roof Sheet Forming Machine

-

Corrugated Sheet Roll Forming Machine

-

Glazed Roll Forming Machine

-

Color Steel Bending Machine

-

Square Ridge Tile Machine

-

High Altitude Roll Forming Machine platform

-

Downspout Roll Forming Machine

-

Cable Tray Roll Forming Machine

-

Standing Seam Roll Forming Machine

-

Cold Roll Forming Machine

-

Double Layer Roll Forming Machine

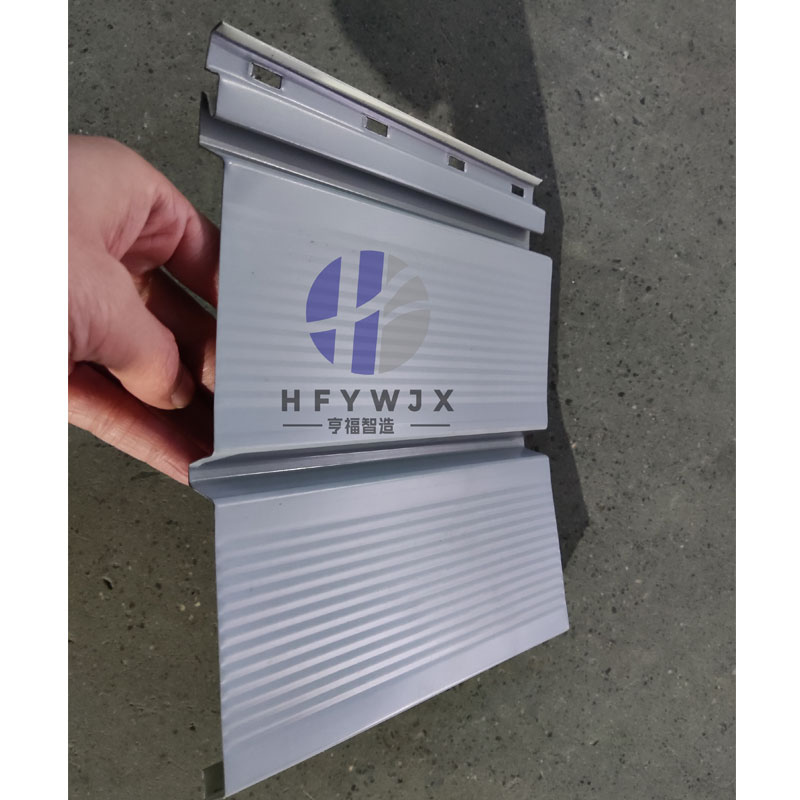

Profile Wall Cladding Panel

This professional production line is engineered for manufacturing high-precision metal profile wall cladding panels,

This professional production line is engineered for manufacturing high-precision metal profile wall cladding panels, ideal for outdoor building facade and interior decoration projects.

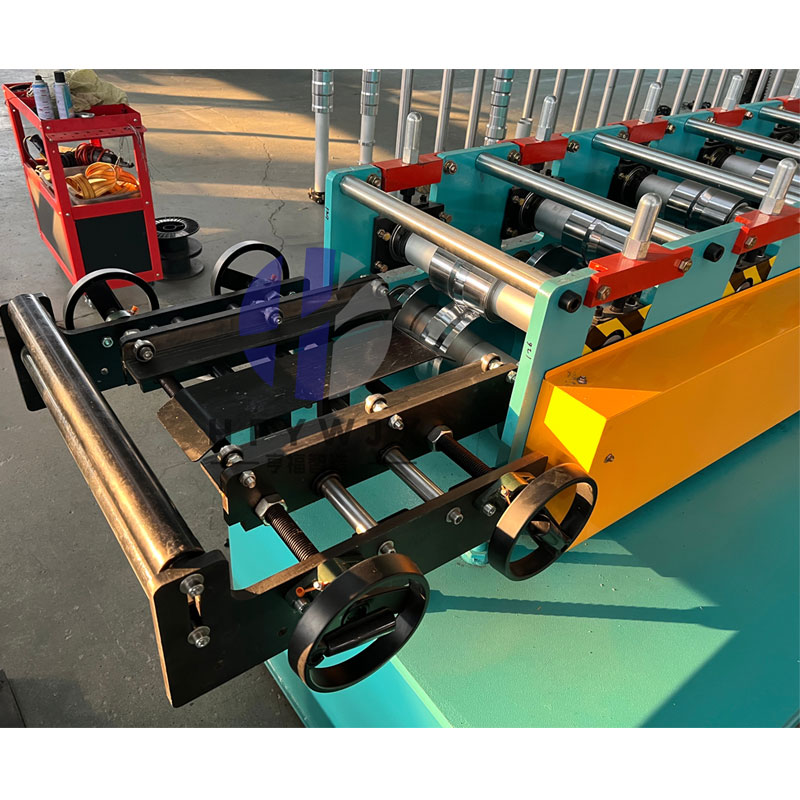

The line features a robust integrated box-type frame for maximum structural stability, paired with 30 sets of forming rolls made from 45# steel with chrome plating, ensuring consistent and durable panel forming. Driven by an 11kw servo motor with 1-inch transmission, it delivers a stable production speed of 15-20 meters per minute.

A dual linear rail shear system with post-forming cutting guarantees burr-free, precise cuts, while an industrial computer PLC frequency control system ensures cutting length accuracy within ≤1mm. The 4kw hydraulic pump and manual double-feed rack streamline material handling, making this a reliable, low-maintenance solution for mass production of high-quality profile wall cladding panels.

| Name Название | Profile Wall Cladding Panel Профильная панель для облицовки стен |

| Machine Frame Рама машины | Integral square frame Цельная квадратная рама |

| Number of roll groups Количество валковых групп | 30 rows formed Сформировано 30 рядов |

| Spindle diameter Диаметр шпинделя | Φ60mm Φ60mm |

| Main motor power Мощность основного двигателя | 11kw 11 кВт |

| Transmission structure Трансмиссионная структура | Chain drive Цепной привод |

| Feeding method Метод подачи | Hand-cranked feeder Ручной подающий механизм |

| Production speed Скорость производства | 15-20m/min 15-220м/мин |

| Control system Система управления | PLC ПЛК |

Our company can produce various types of tile pressing machine products, and the roll forming plate types are diverse.

Q1:Are you a manufacturer?

A1:Yes absolutely. Welcome a lot for your visiting to us.

Q2:Do you have after-sale support?

A2:Yes, we're always here for giving you advice and support for technical details since

we have senior technician.

Q3:Is there quality control when manufacturing the lines?

from laying off the raw material, processing the rollers and the other parts, make

treatment on the roller surface and shaft, assembling, testing and packaging.

Q4:What's your strength comparing to the other supplier?

A4:We'll supplying you the best quality and service. We'll give you good advise beyond

your requirements. The lines are easily for installation and with low mantenance

requirements.

Q5: Any other service?

A5: We can manufacture, design, installation and debug various roll forming machines

including standard and customized machines.

It is free to assemble machine and

train your works, but the buyer should pay for the round-trip airplane ticket, and

arrange

accommodation during that time.