Adapting Metal Roof Machines to Modern Architectural Designs

writer:优化 release time:2025-10-13 16:09:57 Views:162frequency

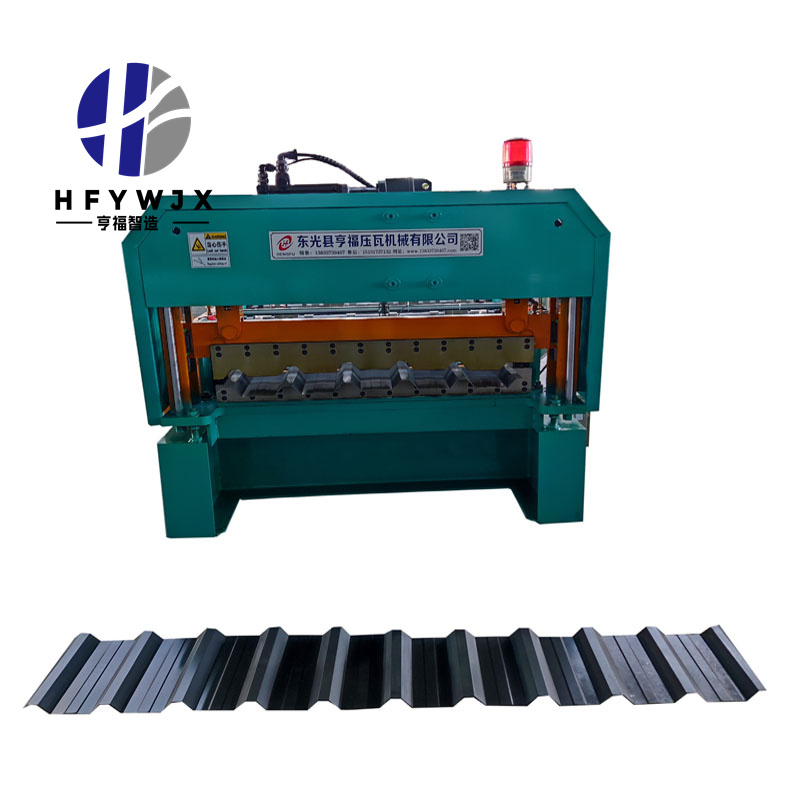

In modern construction, the Metal Roof has become an essential element of both form and function. Known for its longevity, lightweight structure, and versatility, it now dominates contemporary design across residential, industrial, and public buildings.

As architecture embraces curved facades, angular contours, and eco-conscious materials, Metal Roof forming machines have evolved to meet these complex design challenges.

Today, many China manufacturers provide bulk-supply Metal Roof systems equipped with high-precision controls and smart automation — combining design freedom with manufacturing efficiency.

Understanding How Metal Roof Systems Meet Modern Design Needs

The architecture of the 21st century demands flexibility. Buildings no longer follow linear or flat designs; instead, they showcase flowing surfaces and dynamic rooflines. To achieve these effects, precision engineering is key — and this is where advanced Metal Roof machines excel.

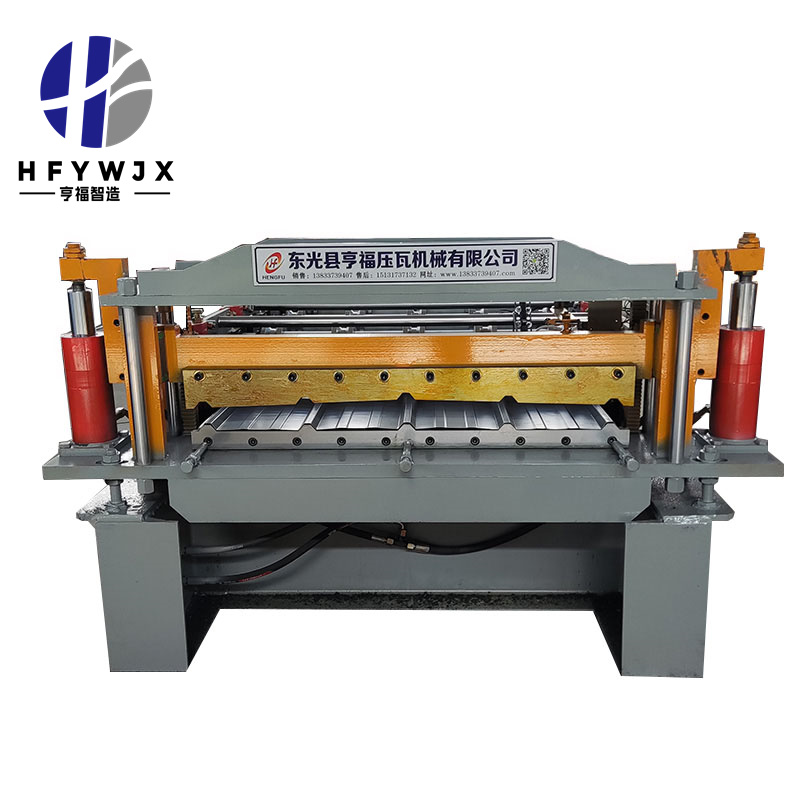

Using hydraulic or servo-controlled forming systems, these machines shape metal coils into panels that perfectly match the architect’s digital blueprints. The result is accurate panel geometry, smooth installation, and lasting performance even under harsh conditions.

Key Technological Advancements in Metal Roof Machinery

1. Enhanced Design Flexibility

Next-generation Metal Roof forming machines can switch quickly between panel types, supporting everything from corrugated to standing seam profiles. Quick-change tooling saves time and supports diversified project requirements.

2. Smart Energy Management

Energy-efficient drives and intelligent PLC systems reduce power consumption while improving output stability — an essential step toward greener manufacturing.

3. High-Speed, Low-Waste Production

Automated cutting, feeding, and stacking systems streamline output and minimize material loss, allowing manufacturers to deliver large orders on schedule.

4. Sustainable and Durable Materials

Metal roofing materials are now produced with recyclable alloys and anti-corrosion coatings, extending lifespan and reducing maintenance needs. This supports global goals for eco-friendly and energy-saving construction.

5. Digital Integration for Design Precision

Advanced China factories are integrating BIM and CAD modeling compatibility, enabling seamless transitions from architectural visualization to real-time production, reducing the margin of error significantly.

Architectural Versatility: Aesthetic Meets Engineering

Metal Roof systems now contribute far beyond simple shelter. They play a key visual role in expressing architectural identity. Whether the design calls for minimalist lines, curved sports arenas, or high-reflectivity commercial roofs, the right forming machine ensures both technical accuracy and creative freedom.

Examples include:

·Curved or vaulted roof panels for exhibition halls or airports;

·Standing seam structures for corporate headquarters;

·Textured or colored finishes for residential or eco-design projects.

Such adaptability bridges creativity and performance — one reason Metal Roofs are shaping the future of sustainable design.

China’s Role in Supplying Advanced Metal Roof Machinery

The global rise of Metal Roof technology owes much to innovation from China manufacturers, who have refined hydraulic systems, automation modules, and customized machine design. Many now provide bulk production capacity, ensuring stable global supply chains at competitive prices.

Sourcing directly from China offers several advantages:

·Tailor-made designs for unique roof profiles or materials;

·Efficient large-scale manufacturing with strict quality control;

·Competitive pricing supported by optimized production lines;

·Comprehensive after-sales service, training, and spare parts support.

These factors make Chinese suppliers reliable partners for engineering firms and construction developers worldwide.

Maintenance and Operational Longevity

A Metal Roof machine is built for endurance, but preventive care remains essential. Regular inspections of the hydraulic system, electrical panels, and forming rollers prevent costly downtime.

Operators should:

·Clean and lubricate key moving parts regularly;

·Replace worn filter elements and cloths;

·Calibrate automation sensors and check hydraulic pressure levels;

·Sanitize forming sections, especially in food or clean-room projects.

Following these steps extends service life and ensures consistent output quality throughout years of operation.

Conclusion: Smarter Roofing for the Future

The Metal Roof has evolved from a basic covering to a centerpiece of sustainable and aesthetic architecture. Through automation, CNC precision, and intelligent control, Automatic Metal Roof machines enable faster, cleaner, and more creative construction practices.

Working directly with a China manufacturer offering bulk supply capacity ensures access to high-efficiency production, engineering expertise, and global delivery reliability.

By embracing next-generation forming technology, builders and architects can transform ideas into long-lasting structures — proof that the modern Metal Roof is as much about innovation as it is about protection.

References

GB/T 7714:Livatyali H, Duggal N, Ahmetoğlu M A, et al. Investigation of crack formation on the galvalume coating of roll formed roof panels[J]. Journal of Materials Processing Technology, 2000, 98(1): 53-61.

MLA:Livatyali, Haydar, et al. "Investigation of crack formation on the galvalume coating of roll formed roof panels." Journal of Materials Processing Technology 98.1 (2000): 53-61.

APA:Livatyali, H., Duggal, N., Ahmetoğlu, M. A., & Altan, T. (2000). Investigation of crack formation on the galvalume coating of roll formed roof panels. Journal of Materials Processing Technology, 98(1), 53-61.