Common Alignment Issues and Solutions in Roll Forming

writer:优化 release time:2025-10-02 17:35:26 Views:169frequency

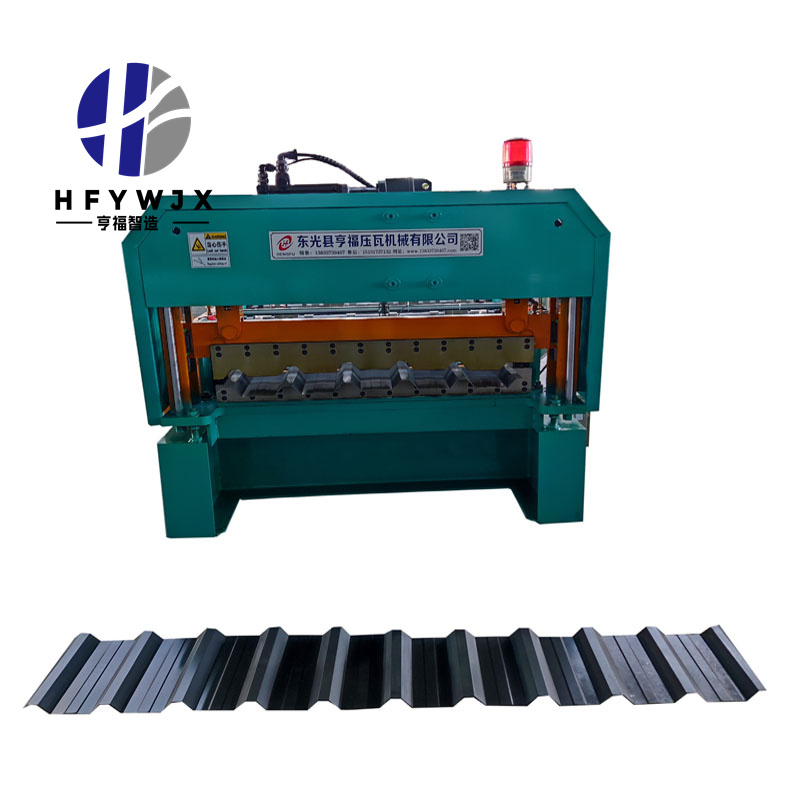

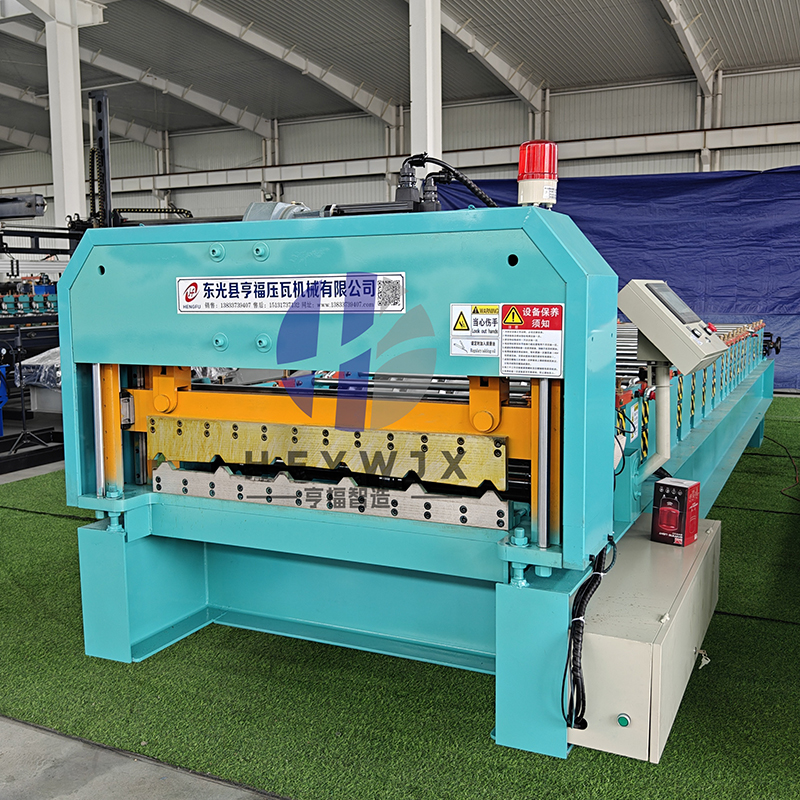

A roll forming machine plays a crucial role in modern sheet metal production. From roofing panels to automotive frames, it delivers consistent profiles at high efficiency. Yet, when alignment problems arise, they can disrupt productivity, reduce product quality, and shorten the lifespan of tooling. Understanding these issues—and how to resolve them—is essential for smooth operations.

This article covers the most frequent alignment issues in roll forming, practical solutions, and why many buyers turn to China manufacturers with proven bulk supply capacity for reliable sourcing.

The Importance of Proper Alignment

Roll forming works by feeding coil stock through a series of rollers, gradually bending it into the desired shape. Even a small deviation in roller positioning or machine setup can cause:

·Distorted or warped profiles.

·Surface scratches or cosmetic defects.

·Increased scrap rates and higher costs.

·Faster wear on rollers and bearings.

Alignment ensures each stage of the process complements the next, maintaining consistent shape, thickness, and surface finish.

Frequent Alignment Challenges

1. Roller Offset

When rollers are not set precisely, material bends unevenly, causing twists and shape defects.

2. Coil Entry Errors

If the coil is fed into the roll forming machine at the wrong angle, misalignment is introduced from the very beginning.

3. Uneven Machine Leveling

A machine that isn’t sitting level across its base will affect roller height and cause product inconsistencies.

4. Roll Gap Variations

Incorrect spacing between rollers results in irregular thickness or unnecessary tool strain.

5. Worn-Out Components

Old shafts, bearings, or bushings allow rollers to vibrate and shift, undermining alignment stability.

Effective Solutions

Precision Setup

Use laser alignment systems or precision gauges during setup to ensure rollers are in exact positions.

Guided Coil Entry

Employ adjustable entry guides so the sheet or coil feeds straight into the machine every time.

Scheduled Calibration

Perform regular checks to verify roller positions and frame leveling to maintain accuracy.

Controlled Roll Gap Adjustment

Follow the manufacturer’s roll gap recommendations to balance durability and profile precision.

Preventive Maintenance

Replace worn parts like bearings or shafts before they compromise roller stability.

Advantages of Correct Alignment

Addressing alignment issues delivers multiple benefits:

·Improved Productivity: Reduced downtime and smoother flow of materials.

·Superior Quality: Finished profiles that match exact specifications.

·Lower Operating Costs: Less waste, fewer defective parts, and extended tooling life.

·Machine Longevity: A properly aligned roll forming machine runs with less strain on its key parts.

Industrial Uses of Well-Aligned Machines

Correct alignment directly impacts output in sectors such as:

·Roofing and cladding panel production.

·Vehicle frame and chassis components.

·Warehouse racking and shelving systems.

·Prefabricated steel building solutions.

Why Work with China Manufacturers?

Global buyers often choose China suppliers because they can prove bulk supply capability, showing they are genuine manufacturers rather than middlemen. Benefits include:

·Lower production costs without cutting corners.

·Reliable shipping for large orders.

·Full support for replacement parts and technical service.

For companies scaling operations, sourcing roll forming machines from China ensures both affordability and dependability.

Conclusion

A well-maintained roll forming machine depends on proper alignment. From coil entry and roller setup to regular calibration and part replacement, each detail contributes to efficiency and product quality.

For businesses seeking dependable machines, partnering with China manufacturers who can prove bulk supply capacity ensures a cost-effective and sustainable solution. With accurate alignment and reliable sourcing, roll forming operations can run at peak performance.

References

GB/T 7714:Lamprecht M, Koçbay E, Leonhartsberger M, et al. Nonlinear mechanical model of the shaft of a roll forming mill and parameter identification[J]. The International Journal of Advanced Manufacturing Technology, 2021, 112(11): 3363-3375.

MLA:Lamprecht, Matthias, et al. "Nonlinear mechanical model of the shaft of a roll forming mill and parameter identification." The International Journal of Advanced Manufacturing Technology 112.11 (2021): 3363-3375.

APA:Lamprecht, M., Koçbay, E., Leonhartsberger, M., Vetyukov, Y., & Bleicher, F. (2021). Nonlinear mechanical model of the shaft of a roll forming mill and parameter identification. The International Journal of Advanced Manufacturing Technology, 112(11), 3363-3375.