Data Monitoring in Roll Forming: From Manual Checks to Real-Time Insights

writer:优化 release time:2025-11-04 14:45:37 Views:94frequency

The Shift Toward Smart Manufacturing

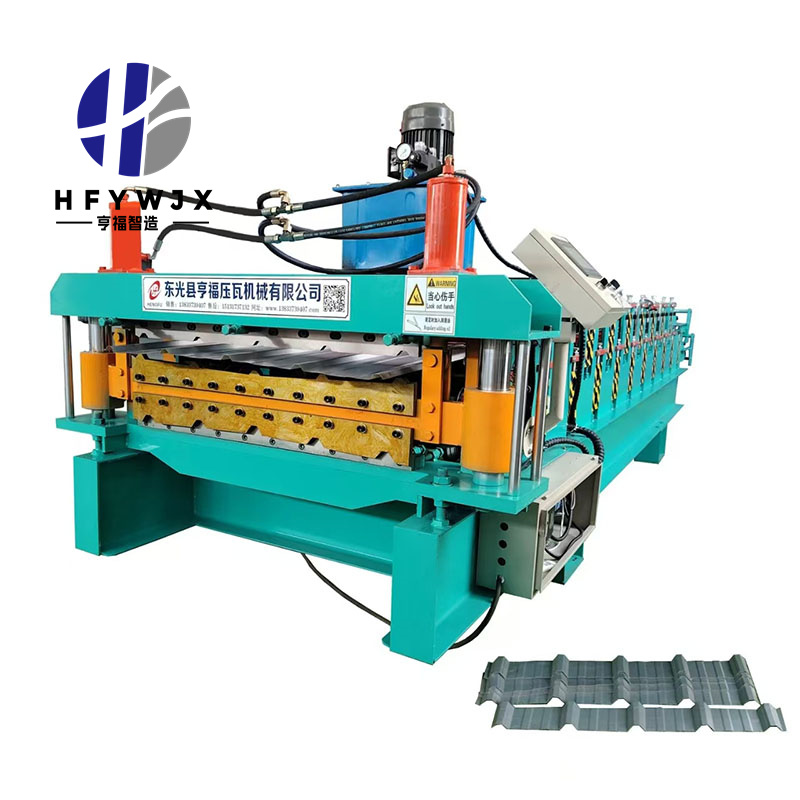

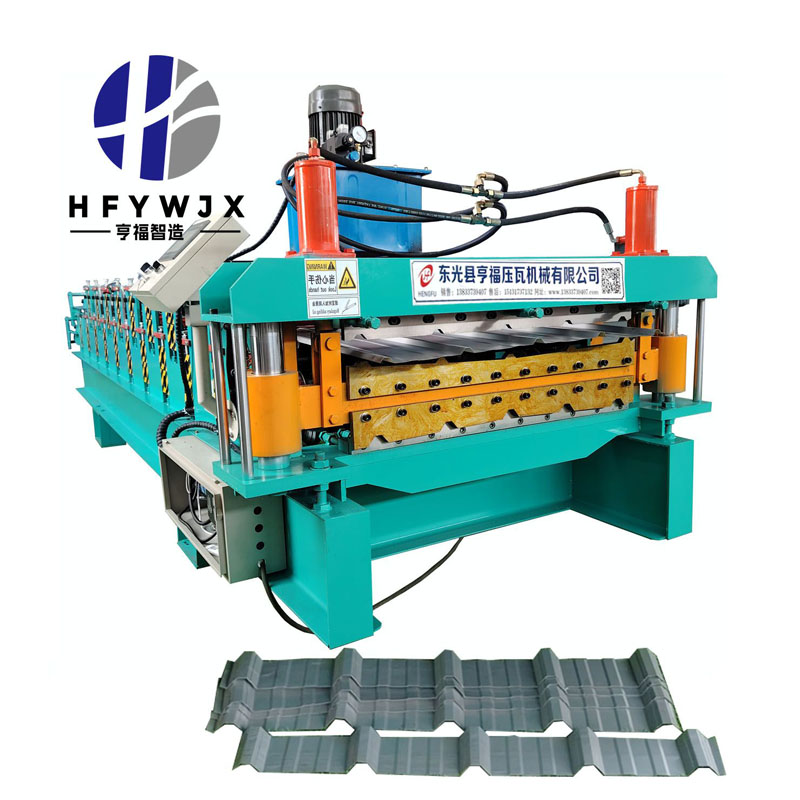

In the era of Industry 4.0, precision and efficiency define success in metal forming. The roll forming machine, once reliant on manual checks and visual inspections, is now evolving into a digitally monitored production powerhouse.

As global demand for high-quality metal profiles increases, China roll forming machine manufacturers are integrating smart data systems to monitor every part of the process — from raw material feeding to final product delivery. This shift toward real-time data insights helps reduce waste, improve consistency, and extend equipment life.

1. Why Data Monitoring Matters in Roll Forming

A roll forming machine operates continuously, shaping long strips of metal into precise profiles. Any deviation in pressure, alignment, or material feed rate can cause costly defects. Traditionally, operators relied on manual checks to detect errors — a method that’s both time-consuming and inconsistent.

Today, data monitoring changes that. With integrated sensors, PLC systems, and cloud-based analytics, manufacturers can now track hundreds of variables simultaneously. The result is predictable performance and data-backed decision-making that ensures top-tier panel quality.

2. From Manual Checks to Digital Precision

Manual Era

Operators once used gauges and calipers to check roller positions, sheet thickness, and line speed. Adjustments were reactive — issues were discovered only after the product showed visual defects.

Digital Era

Now, digital sensors collect continuous data on:

·Roller torque and pressure

·Sheet thickness and temperature

·Lubrication and vibration levels

·Motor current and line speed

This data feeds into a central control dashboard, allowing engineers to analyze and optimize parameters in real-time.

For China-based roll forming equipment manufacturers, these smart systems not only boost reliability but also make remote technical support and predictive maintenance possible for global buyers.

3. Key Benefits of Real-Time Monitoring

Implementing data monitoring in a roll forming line delivers measurable advantages:

·Higher Production Accuracy

Real-time sensors detect micro-deviations before they lead to visible flaws. This ensures consistent panel geometry and smooth surface finish.

·Predictive Maintenance

Historical data helps forecast component wear — such as bearings, rollers, or hydraulic systems — allowing replacement before failure occurs. This minimizes downtime and repair costs.

·Quality Traceability

Each batch of metal profiles can be linked to its production data, helping trace root causes of defects and ensuring compliance with export standards.

·Energy Efficiency

Monitoring power consumption per forming stage identifies inefficient stations or motors, allowing operators to adjust parameters and reduce energy waste.

·Global Remote Access

Cloud-based dashboards let managers and technicians monitor the production line from anywhere — ideal for factories serving global distributors or export clients.

4. Components of an Intelligent Roll Forming Monitoring System

A modern data-driven roll forming machine usually includes the following:

·Sensors: Measure torque, pressure, speed, and vibration.

·PLC + HMI Interface: Collects and visualizes production data.

·Industrial IoT Module: Sends real-time data to cloud platforms.

·Data Analytics Software: Processes and interprets trends for decision-making.

·Alarm and Safety Protocols: Trigger alerts for abnormal readings.

Chinese manufacturers are increasingly offering custom-built monitoring systems, designed to fit specific panel profiles, production speeds, and export market requirements.

5. Implementation Challenges and Solutions

While digital transformation sounds promising, it requires planning and integration expertise.

Common Challenges:

·Lack of standardization in older machine models

·High initial investment for sensors and IoT modules

·Limited operator training on data interpretation

Solutions from Leading China Manufacturers:

·Retrofit kits that upgrade traditional roll forming machines with modern sensors

·Modular control panels for step-by-step digitalization

·On-site or remote training for factory engineers and operators

By combining local manufacturing capability with intelligent automation, China roll forming machine suppliers deliver both affordability and innovation.

6. Case Insight: Turning Data into Action

Imagine a production line forming steel wall panels at 30 meters per minute. Sensors detect a slight increase in roller torque and temperature on Station 5.

Before manual inspection could notice the issue, the system triggers an alert — suggesting misalignment or lubrication loss. Maintenance is performed immediately, preventing potential surface scratches and unplanned downtime.

This predictive approach, now common among advanced Chinese factories, shows how data transforms maintenance from reactive to proactive.

7. The Future of Data-Driven Roll Forming

As IoT, AI, and machine vision technologies mature, next-generation roll forming machines will go beyond monitoring — they’ll self-adjust in real time.

Future systems may feature:

·AI algorithms that auto-correct roller pressure

·Cloud databases comparing thousands of production runs

·Digital twins for virtual testing and setup optimization

This evolution ensures that manufacturers stay competitive, delivering precision-engineered panels while maintaining low production costs.

Conclusion: Smarter Machines, Stronger Output

Data monitoring has become the heartbeat of modern roll forming machine technology. For builders, distributors, and fabricators, partnering with a China roll forming machine manufacturer that offers intelligent monitoring solutions means higher efficiency, reduced downtime, and consistent quality assurance.

With continuous innovation and bulk supply capabilities, China’s professional factories are proving that smart manufacturing is not a luxury — it’s the new standard for precision and profitability.

References

GB/T 7714:Kubik C, Becker M, Molitor D A, et al. Towards a systematical approach for wear detection in sheet metal forming using machine learning[J]. Production Engineering, 2023, 17(1): 21-36.

MLA:Kubik, Christian, et al. "Towards a systematical approach for wear detection in sheet metal forming using machine learning." Production Engineering 17.1 (2023): 21-36.

APA:Kubik, C., Becker, M., Molitor, D. A., & Groche, P. (2023). Towards a systematical approach for wear detection in sheet metal forming using machine learning. Production Engineering, 17(1), 21-36.