Double Layer Roll Forming Machine Calibration: Step-by-Step Guide

writer:优化 release time:2025-12-05 11:55:53 Views:112frequency

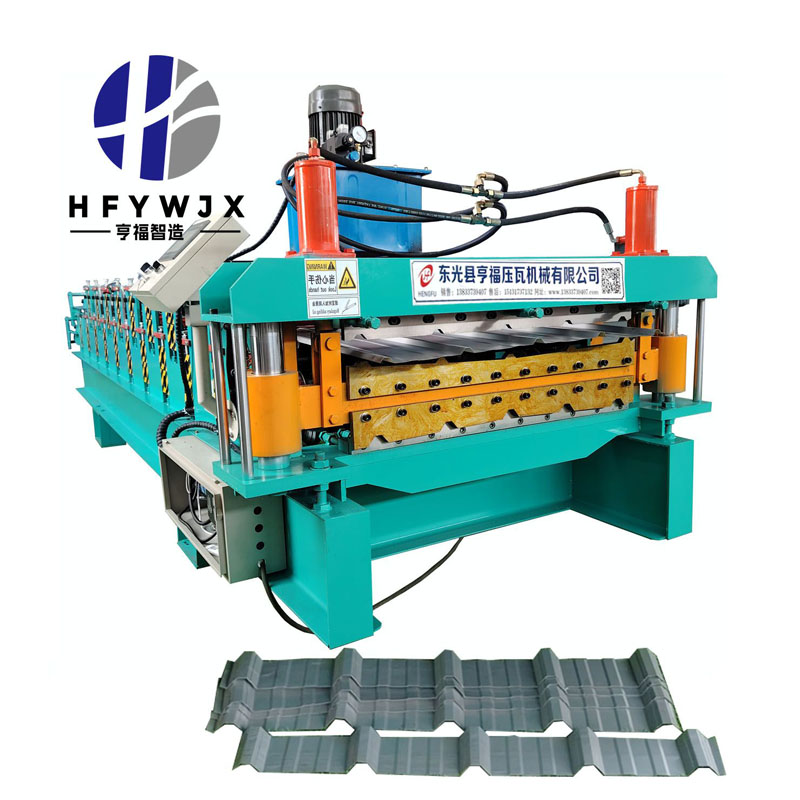

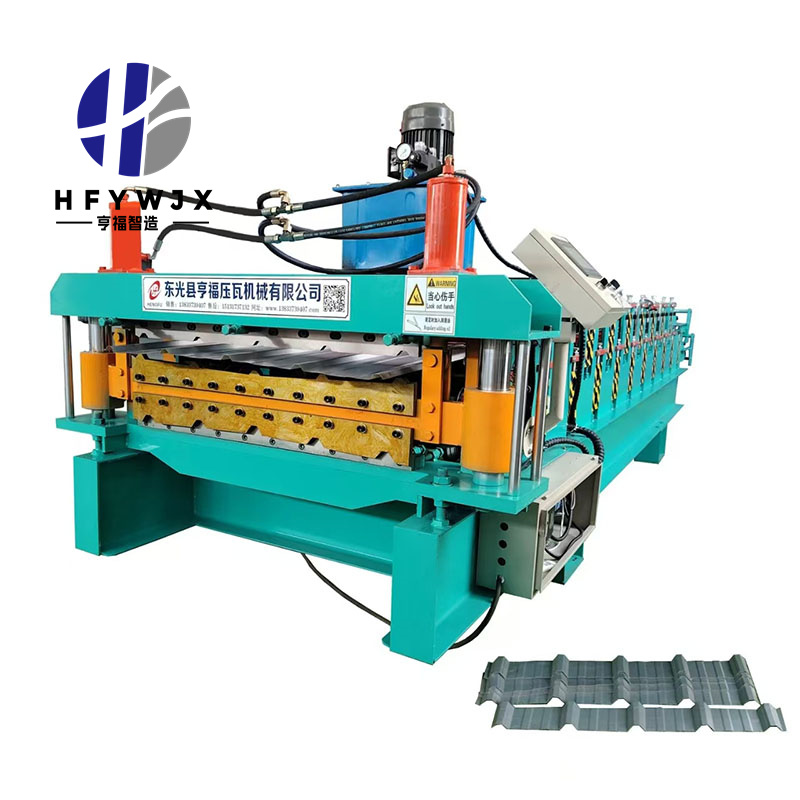

Why do so many manufacturers trust a Double Layer Roll Forming Machine from us?

Because in modern sheet-metal production, nothing beats a machine that delivers two fully independent forming profiles, ultra-stable accuracy, and long-term bulk production reliability—all in one compact structure.

And we don’t just build machines—we build machines that stay accurate.

But here’s the real question every serious producer asks:

What separates a good Double Layer Roll Forming Machine from an exceptional one?

Our answer is simple: calibration—and we know calibration better than anyone.

When you source equipment from a manufacturer like us, with large-scale production capability and rock-solid bulk supply consistency, you expect precision. And our machines deliver exactly that—but only if you follow a proper calibration workflow.

This guide gives you the same process our technicians use in-house.

1. Why Is Calibration So Critical?

Some manufacturers assume double-deck machines are simply “two in one.”

But ask yourself:

If the top layer goes out of alignment, what happens to the bottom?

If one roller station drifts, how fast will both profiles degrade?

Exactly—calibration becomes twice as important.

Proper calibration prevents:

·Geometry instability

·Edge distortion & surface defects

·Uneven pressure and premature roller wear

·Material wandering

·Layer-to-layer height/width mismatches

·Excess vibration or unexpected noise

When calibrated using our recommended procedures, both profiles maintain accuracy across long production cycles—even at full operating speed.

2. What Should Be Done Before Calibration? (Our Technicians’ Checklist)

Before touching any roller:

a. Safe Shutdown

We always say: “A safe machine is a precise machine.”

Power off, depressurize hydraulics, lock out all energy sources.

b. Base Frame Inspection

Many users forget this and wonder why accuracy drifts.

With a double-deck structure, even slight foundation deviation affects both layers.

c. Full Roller Cleaning

Clean rollers = accurate measurements = reliable adjustments.

d. Prepare Professional Measurements

The same tools we use during factory calibration:

·Laser or straightedge

·Feeler gauges

·Dial indicators

·Digital calipers

·Torque wrench

·Plumb bob

This is why our calibrations achieve industry-leading consistency.

3. Our Signature Step-by-Step Calibration Workflow

Step 1: Entry Guide Alignment

Want to eliminate strip wandering from the very beginning?

Align the entry guides perfectly.

·Adjust width, but avoid gripping the strip

·Use a laser to confirm left-right balance

·Make sure both deck centerlines match

·Symmetry is everything

A crooked entry = crooked everything.

Step 2: Roller Shaft Parallelism

Here’s where many lower-end manufacturers fail—but we don’t.

Our machines keep shaft tolerances extremely tight, but calibration ensures:

·Horizontal parallelism

·Vertical consistent height

·Zero roller twist

Use straightedges and feeler gauges.

Parallel shafts = uniform forming pressure.

Step 3: Roller Gap Adjustment

Do you want perfect forming progression?

Then roller gaps must follow designed pass distribution, not guesswork.

·Set gaps according to actual coil thickness

·Verify with gauges

·Ensure reduction is incremental and correct

Incorrect gaps = dimensional errors + surface scratching.

Step 4: Station-by-Station Roller Alignment

Each forming pass must guide the material—not fight it.

·Identify the base reference station

·Align all following stations using dial indicators

·Perform a manual pull-through

This is one of the reasons customers say our calibration procedures produce “butter-smooth forming.”

Step 5: Cutter System Calibration

A perfect profile without perfect length? No way.

·Check vertical blade movement

·Ensure zero lateral drift

·Test-cut several pieces

·Measure length and squareness

Our cutting units are engineered for high-speed accuracy, but calibration guarantees perfection.

Step 6: Low-Speed Test Run

This is where sharp technicians shine.

·Run at low speed

·Listen for abnormal roller sound

·Monitor temperature

·Inspect strip surface

Small tweaks here prevent big problems later.

Step 7: High-Speed Verification

Once stable at low speed, push it.

·Full-speed forming

·Batch test both layers

·Measure repeatedly

·Confirm long-run consistency

Only a professionally built Double Layer Roll Forming Machine from a high-capacity manufacturer can stay this stable at high speeds.

4. What Maintenance Keeps Calibration Stable? (Our Pro-Level Advice)

Even the best machine requires responsible care:

·Recheck alignment every few weeks

·Keep rollers clean and lubricated

·Replace bearings/rollers before major wear occurs

·Inspect coil edges

·Recalibrate cutting length regularly

·Monitor vibration patterns

Do this, and your machine will run like new for years—even under continuous bulk production.

Conclusion: Why Do Our Machines Stay Accurate Longer?

Because we don’t just design Double Layer Roll Forming Machines.

We engineer them for durability, precision, and efficient mass production—and we’ve mastered the calibration science that keeps them performing at their peak.

If you follow the calibration workflow above, your machine will:

·Deliver extremely stable profile dimensions

·Maintain long-term forming accuracy

·Reduce roller wear

·Minimize scrap

·Maximize production uptime

That’s why customers say:

“Your machines just run better.”

And we agree—because we build them that way.

References

GB/T 7714:Sheet metal forming: processes and applications[M]. ASM international, 2012.

MLA:Altan, Taylan, and A. Erman Tekkaya, eds. Sheet metal forming: processes and applications. ASM international, 2012.

APA:Altan, T., & Tekkaya, A. E. (Eds.). (2012). Sheet metal forming: processes and applications. ASM international.