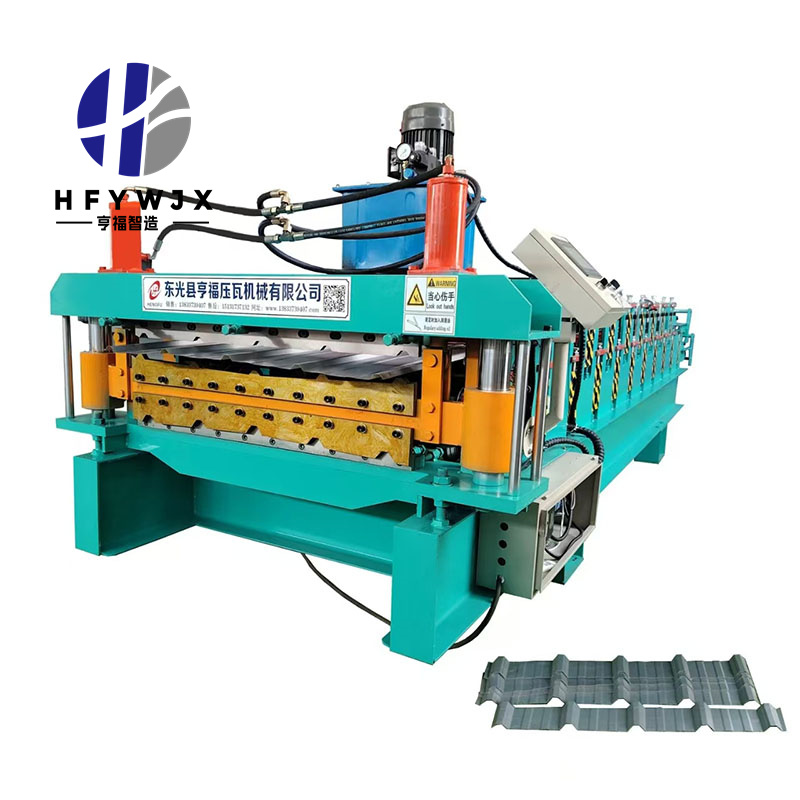

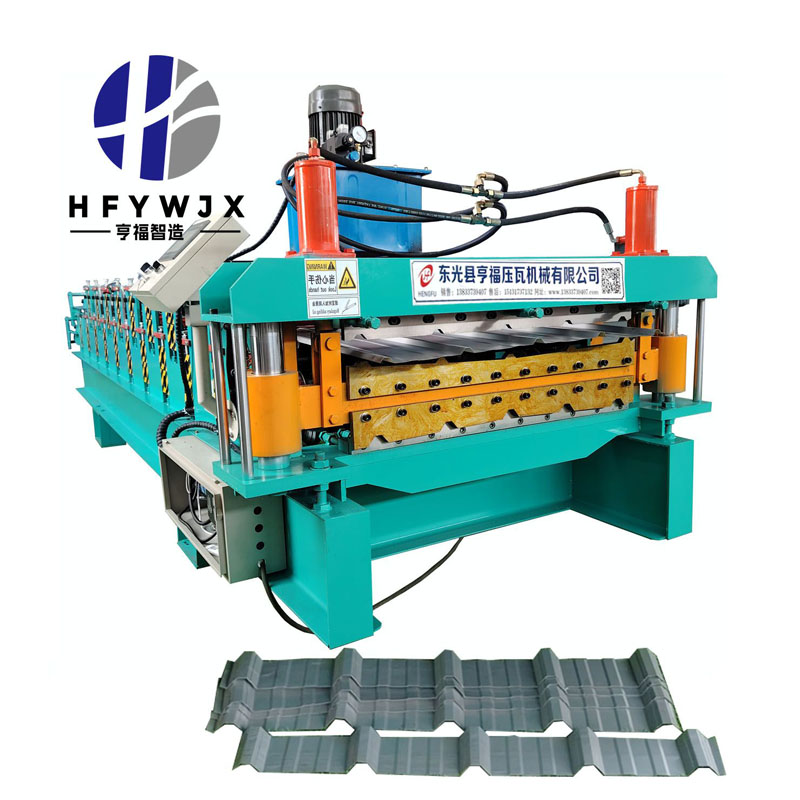

Double Layer Roll Forming Machine: Double the Advantage

writer:优化 release time:2025-09-21 13:07:13 Views:185frequency

Smarter Manufacturing for a Demanding Market

In today’s construction sector, speed and variety are no longer optional—they are survival tools. Roofing suppliers are expected to deliver large volumes of panels while adapting to shifting architectural trends. Relying on a single-profile roll forming line often forces businesses to choose between capacity and flexibility.

The Double Layer Roll Forming Machine provides a direct answer. By combining two panel profiles within one compact production line, manufacturers can increase throughput without investing in additional machines or workshop space. For international buyers, working with a Chinese manufacturer offering bulk supply and verified factory proof ensures both affordability and reliability.

What Sets the Double Layer Machine Apart?

Unlike conventional systems that handle only one design, a double layer model integrates two different panel profiles into a single frame and drive system. Operators can switch between them quickly, allowing manufacturers to serve broader markets with minimal downtime.

Key Advantages

·Space Optimization – One system replaces two, saving valuable floor area.

·Quicker Changeovers – Switching profiles is fast and simple.

·Lower Capital Outlay – Less costly than purchasing two separate lines.

·Higher Productivity – Output increases without expanding infrastructure.

Why the Double Layer Design Delivers

The machine’s performance comes from its engineering and automation features:

1.Reinforced Structure – A solid frame maintains alignment, preventing vibration and ensuring consistent panel quality.

2.PLC-Controlled Automation – User-friendly systems allow seamless profile switching with fewer errors.

3.Energy Efficiency – Running two profiles within one line consumes less power than two separate machines.

4.Durable Rollers – Hardened materials and advanced coatings extend lifespan and minimize maintenance.

Together, these elements make the Double Layer Roll Forming Machine a long-term asset for manufacturers aiming to scale efficiently.

Why Global Buyers Prefer Chinese Suppliers

The shift toward sourcing from China is driven by practical advantages:

·Bulk Supply Capability – Large factories meet high-volume orders consistently.

·Factory Proof – Verified documentation proves in-house production and builds buyer confidence.

·Competitive Costs – Scale and efficiency make advanced equipment affordable.

·Export Expertise – Decades of international trade experience ensure smooth delivery worldwide.

For global distributors and contractors, these strengths reduce risk and accelerate payback periods.

A Buyer’s Checklist for Smarter Investment

Before committing to a purchase, manufacturers should:

·Review Frame Strength – A reinforced structure ensures accuracy at high speeds.

·Request Certification – Always ask for factory proof before signing contracts.

·Check Energy Consumption – Choose machines with efficient power usage to reduce operational costs.

·Consider Bulk Orders – Partner with suppliers offering bulk supply to lower per-unit expenses.

This approach ensures the equipment performs reliably under real-world production pressures.

The Outlook for 2025 and Beyond

The construction market will continue demanding more panels, faster, and in multiple styles. A Double Layer Roll Forming Machine equips manufacturers to keep up by doubling profile options without doubling costs. With support from a Chinese manufacturer experienced in bulk supply and international certifications, global buyers can scale operations confidently while keeping overheads under control.

Conclusion: Two Profiles, One Competitive Edge

The Double Layer Roll Forming Machine represents the next stage in roofing sheet production. By integrating two profiles into one efficient system, it allows companies to boost output, minimize downtime, and conserve workshop space.

For international manufacturers, sourcing from a Chinese manufacturer with both bulk supply and factory proof is the smartest path forward. This combination ensures cost savings, production stability, and long-term competitiveness in a fast-evolving market.

References

GB/T 7714:Woo Y Y, Oh I Y, Hwang T W, et al. Analysis of shape defects during flexible roll forming of steel/aluminum double-layered blanks[J]. International Journal of Material Forming, 2020, 13(6): 861-872.

MLA:Woo, Young Yun, et al. "Analysis of shape defects during flexible roll forming of steel/aluminum double-layered blanks." International Journal of Material Forming 13.6 (2020): 861-872.

APA:Woo, Y. Y., Oh, I. Y., Hwang, T. W., & Moon, Y. H. (2020). Analysis of shape defects during flexible roll forming of steel/aluminum double-layered blanks. International Journal of Material Forming, 13(6), 861-872.