Double Layer Roll Forming Machine: Improve Speed and Accuracy

writer:优化 release time:2025-11-05 14:48:51 Views:88frequency

Building Efficiency into Modern Metal Forming

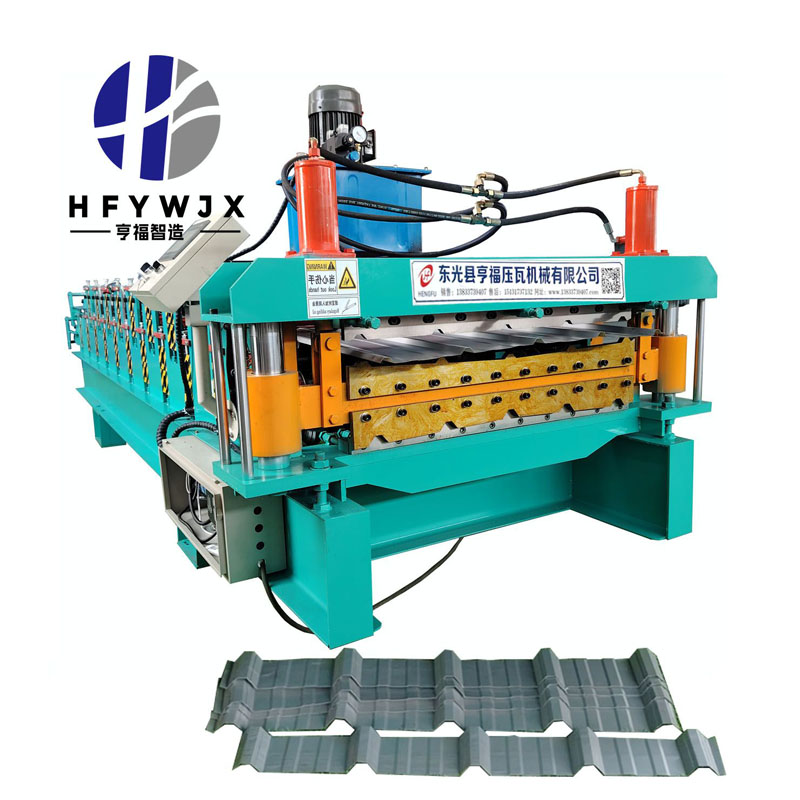

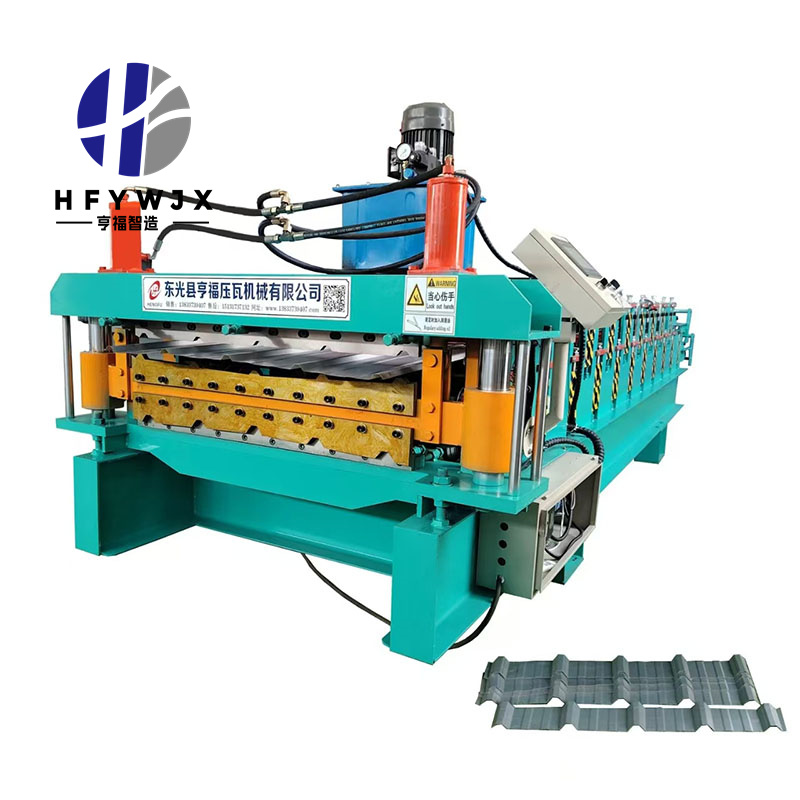

Within today’s metal fabrication sector, success depends on two elements — speed and accuracy. The Double Layer Roll Forming Machine combines both goals, delivering two unique sheet profiles within one integrated frame.

Yet the dual-layer system presents an engineering challenge: how to sustain high throughput without compromising sheet geometry. For a China-based roll forming machine manufacturer, optimization involves more than fast operation — it’s about aligning automation, precision tooling, and synchronized controls for consistent mass production results.

1. Understanding the Role of Double Layer Systems

A double layer roll forming unit uses a single base with two independent roller sets, usually for manufacturing roof and wall panels. The top and bottom layers can switch via a hydraulic or electrical system, avoiding manual tooling changes and boosting flexibility.

This configuration helps factories save floor space while improving production turnover. However, the more compact the design, the greater the need for precise mechanical synchronization between the upper and lower forming layers. A small misalignment can cause shape distortion, coating damage, or feeding errors — all of which impact workflow efficiency.

2. Key Obstacles to Optimized Performance

Before enhancing the workflow, it’s critical to understand what limits it. The most common issues include:

·Switching delays: Layer transitions take valuable seconds off each run.

·Uneven roller wear: One layer may endure heavier use than the other.

·Feeding inconsistencies: Material slippage or tension variation leads to profile inaccuracy.

·Thermal effects: Continuous high-speed forming builds up heat, affecting metal elasticity.

For Chinese roll forming machine suppliers, solving these bottlenecks means optimizing mechanical components, software logic, and operator habits simultaneously.

3. Smart Automation and Digital Control

One of the fastest ways to boost output is by integrating intelligent PLC and servo-driven systems. Unlike older analog controls, digital setups offer instant feedback, allowing precise coordination between each forming station.

Core Enhancements Include:

·Servo-controlled layer switching for faster, repeatable transitions.

·Torque and load sensors to detect strain and balance speed accordingly.

·HMI dashboards that visualize pressure, vibration, and sheet progress.

·Automatic lubrication systems that reduce friction and downtime.

These features — now standard in many China double layer roll forming machines — make the workflow smoother, safer, and easier to calibrate, especially during long production runs.

4. Material Flow and Feeding Optimization

Even a well-tuned forming unit can fail if material movement is inconsistent. Feeding precision directly determines final sheet accuracy and productivity.

Best Optimization Practices:

·Use motorized decoilers with tension feedback sensors.

·Adopt servo feeders to maintain stable sheet pitch control.

·Apply anti-scratch guide rollers to protect pre-painted or galvanized sheets.

·Add automated stacking systems for uninterrupted sheet handling.

For high-volume operations, these enhancements ensure steady throughput while minimizing human error — something China roll forming machine factories often emphasize when building export-grade equipment.

5. Balancing Production Speed and Dimensional Stability

Achieving both high speed and perfect accuracy is the core balancing act in double layer forming. Pushing too fast can create stress in the metal, causing bending, springback, or even micro-cracks in coatings.

To maintain equilibrium:

·Adjust roller gaps according to thickness variations.

·Match line speed with sheet tensile strength and coating type.

·Conduct regular roller cleaning and calibration.

·Monitor vibration and noise as indicators of system stress.

Data analytics tools can visualize this balance in real time, letting operators make fine adjustments for maximum stability.

6. Predictive Maintenance and Workflow Longevity

A high-speed forming line is only as reliable as its maintenance strategy. Instead of reacting to failures, factories now rely on predictive maintenance supported by data monitoring.

Routine Checklist

·Daily: Wipe and inspect roller surfaces.

·Weekly: Check layer switching alignment.

·Monthly: Examine hydraulic circuits and motor couplings.

·Yearly: Polish rollers and recalibrate sensors.

Some advanced China double layer roll forming machine manufacturers now integrate self-diagnostic systems that automatically alert operators to anomalies, reducing downtime and protecting equipment investment.

7. The Power of Data and Continuous Improvement

Real-time monitoring has redefined how production efficiency is measured. Each forming cycle now produces valuable data — torque readings, sheet count, temperature, and vibration metrics — all stored for performance analysis.

By connecting these data points to cloud dashboards or IoT systems, managers can identify trends, predict wear patterns, and fine-tune the process without halting production.

This data-centric workflow ensures every batch meets global quality standards while allowing bulk suppliers from China to maintain consistent output for international partners.

Conclusion: Efficiency Meets Precision

Optimizing the workflow of a Double Layer Roll Forming Machine is about mastering control — balancing mechanical rhythm, automation intelligence, and continuous monitoring.

By implementing servo-driven adjustments, predictive maintenance, and smart feeding systems, manufacturers can dramatically boost throughput while keeping precision intact.

For global builders and distributors, working with a China double layer roll forming machine manufacturer and bulk supplier means access to production-proven technology, professional customization, and stable long-term performance — hallmarks of a trusted industrial partner in modern sheet forming.

References

GB/T 7714:Essa A, Decker M, Padharia H, et al. Inline monitoring of material properties and product shape in roll forming[C]//MATEC Web of Conferences. EDP Sciences, 2025, 408: 01021.

MLA:Essa, Abdelrahman, et al. "Inline monitoring of material properties and product shape in roll forming." MATEC Web of Conferences. Vol. 408. EDP Sciences, 2025.

APA:Essa, A., Decker, M., Padharia, H., & Weiss, M. (2025). Inline monitoring of material properties and product shape in roll forming. In MATEC Web of Conferences (Vol. 408, p. 01021). EDP Sciences.