Enhancing Surface Durability in Wall Sheet Roll Forming Machines

writer:优化 release time:2025-11-03 10:20:11 Views:200frequency

Surface Durability Defines Performance

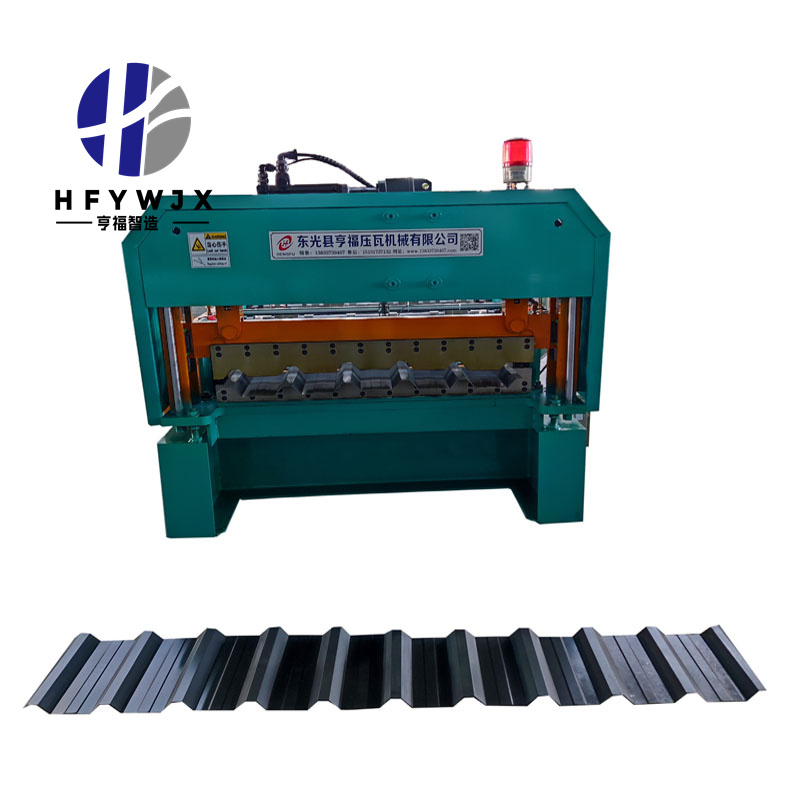

The efficiency and longevity of a Wall Sheet Roll Forming Machine depend heavily on how well its working surfaces resist wear and corrosion. Every panel that passes through the rollers represents both precision and pressure — and over time, that contact takes a toll.

If surface protection is ignored, it can lead to scratches, uneven profiles, and faster coating degradation. For a professional China wall sheet roll forming machine manufacturer, improving durability is about more than longevity; it’s about ensuring consistent panel quality and reducing production downtime.

Understanding What Affects Surface Durability

In a roll forming system, surface durability refers to the machine’s ability to maintain smooth roller performance and protect sheet coatings under continuous high-speed operation. The main factors influencing this include:

·Roller material composition and hardness

·Protective coatings or surface treatments

·Lubrication and temperature control

·Alignment accuracy and maintenance routines

Each of these directly impacts the wall sheet’s surface finish and overall production stability.

1. Selecting the Right Roller Material

Roller material is the foundation of durability. Different steels and coatings react differently to heat, pressure, and friction.

Common materials used in wall sheet roll forming machines include:

·Cr12MoV Tool Steel – A popular choice in Chinese manufacturing plants for its wear resistance and stability.

·D2 Tool Steel – Offers superior hardness and maintains precision under repetitive load.

·GCr15 Bearing Steel – Known for excellent surface smoothness and cost balance.

·Tungsten Carbide Coated Rollers – Ideal for bulk production with minimal maintenance.

A China-based roll forming machine supplier can tailor roller material and surface hardness to match your specific panel type and production frequency.

2. Surface Treatments and Protective Coatings

Even the toughest steel benefits from surface enhancement. Coating technologies dramatically improve roller life and protect against friction damage.

Effective Treatment Options:

·Hard Chrome Plating: Creates a highly polished, corrosion-resistant surface.

·Nitriding: Adds nitrogen to the surface layer, increasing hardness and reducing friction.

·PVD (Physical Vapor Deposition): Offers an ultra-thin yet strong wear-resistant coating.

·Ceramic or TiN Coatings: Withstand extreme conditions and ensure consistent performance in long production runs.

Regular recoating ensures smooth sheet flow and reduces micro-scratches, especially when forming galvanized or pre-painted steel panels.

3. Lubrication and Cooling — The Hidden Defenders

Friction and temperature spikes are silent killers of both rollers and sheet coatings. Proper lubrication not only reduces wear but also helps maintain stable shaping precision.

Best practices include:

·Using high-quality synthetic lubricants designed for metal forming.

·Maintaining uniform oil distribution throughout every forming station.

·Integrating air-mist cooling or circulating systems to keep temperatures balanced.

In high-speed or continuous operations, these measures can extend the life of rollers by over 50% and minimize visible surface wear on the sheets.

4. Routine Maintenance and Inspection

No matter how strong your machine, poor upkeep will destroy durability faster than anything else. Establishing a preventive maintenance program is essential for stable performance.

Suggested Routine:

·Daily: Clean roller surfaces using non-abrasive wipes.

·Weekly: Check roller alignment and pressure settings.

·Monthly: Inspect bearings, guide rails, and hydraulic systems for leaks or noise.

·Annually: Regrind or recoat worn rollers and recalibrate forming stands.

Many China wall sheet roll forming machine manufacturers now design machines with automatic lubrication and alignment sensors to simplify maintenance and reduce operator error.

5. Protecting Sheet Surface During Handling

Durability doesn’t end once the sheet exits the forming line. Improper handling during stacking or packaging can ruin surface quality.

To avoid this:

·Use non-marking conveyor rollers or soft pads.

·Apply temporary plastic protection film on coated panels.

·Employ automated stacking systems that minimize impact and friction.

This ensures the panels reach customers in perfect condition, preserving the visual and structural integrity expected from premium wall sheets.

6. Process Optimization and Monitoring

Modern production lines are increasingly equipped with digital monitoring systems that track roller wear, temperature, and vibration in real-time. Early detection allows maintenance teams to correct problems before they affect surface quality.

In addition, consistent quality control tests—like gloss, coating thickness, and surface roughness measurements—help verify that every sheet meets export standards.

Top China roll forming equipment suppliers often include training and calibration guidance for buyers, supporting long-term reliability.

Conclusion: Durability Is an Investment, Not an Option

Improving surface durability in Wall Sheet Roll Forming Machines is the key to achieving consistent output, reducing maintenance costs, and enhancing product reputation.

By combining high-quality roller materials, protective coatings, proper lubrication, and disciplined maintenance, manufacturers can significantly increase production efficiency and extend machine lifespan.

For global distributors and builders, sourcing from a trusted China wall sheet roll forming machine manufacturer and bulk supplier ensures precision-built equipment, factory-tested durability, and dependable after-sales support — all essential to maintaining a competitive edge in today’s construction market.

References

GB/T 7714:Gao J, Cai Z, Zhang X, et al. Shape prediction in continuous roll forming of sheet metal based on rigid rolls[J]. International Journal of Mechanical Sciences, 2024, 279: 109513.

MLA:Gao, Jiaxin, et al. "Shape prediction in continuous roll forming of sheet metal based on rigid rolls." International Journal of Mechanical Sciences 279 (2024): 109513.

APA:Gao, J., Cai, Z., Zhang, X., & Zhang, Z. (2024). Shape prediction in continuous roll forming of sheet metal based on rigid rolls. International Journal of Mechanical Sciences, 279, 109513.