High-Strength Steel Roll Forming: Key Issues and Practical Solutions

writer:优化 release time:2025-09-28 11:56:02 Views:167frequency

Why High-Strength Steel Matters

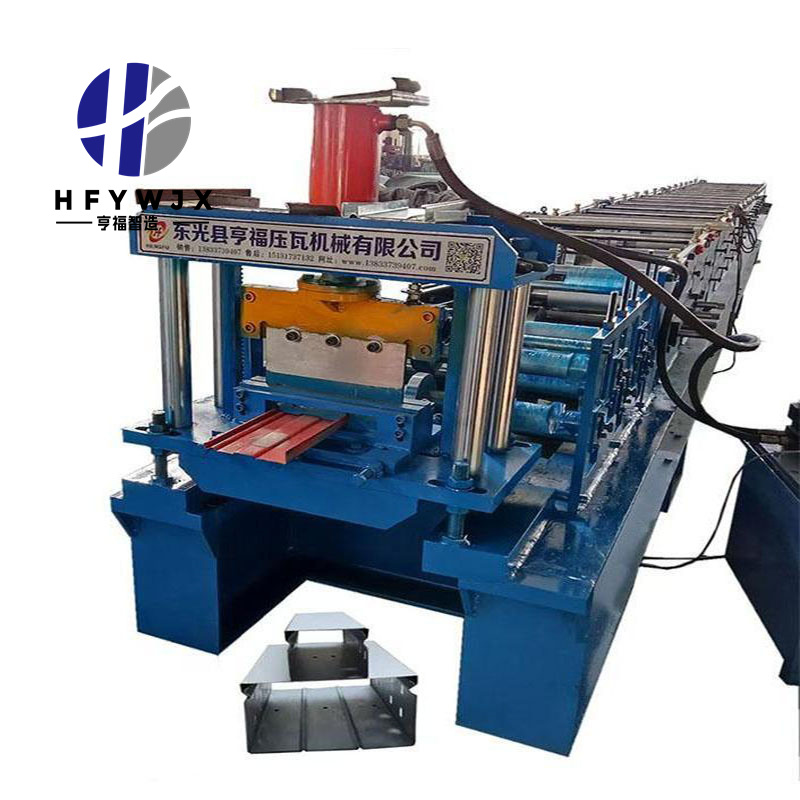

High-strength steel (HSS) is now a staple in automotive, construction, and infrastructure projects thanks to its high durability and reduced weight. However, shaping this material comes with challenges. That’s where the Roll Forming Machine plays a pivotal role. Compared to alternative equipment, roll forming provides accuracy and mass production benefits. Partnering directly with Chinese manufacturers offering bulk orders gives businesses reliable performance and competitive costs.

What Does Roll Forming Mean for High-Strength Steel?

Roll forming is a continuous bending process that transforms long strips of HSS into precise profiles through a sequence of rollers. Because HSS is harder and less formable than mild steel, the process requires heightened precision and robust equipment.

Notable Features of Roll Forming Machines:

·Continuous Runs: Handles extended strips seamlessly.

·High Precision: Produces accurate, repeatable profiles.

·Adaptability: Can accommodate varied gauges and designs.

·Durability: Designed to manage demanding materials like HSS.

Major Challenges in HSS Roll Forming

1. Springback

Elastic recovery in HSS makes dimensional control more difficult.

2. Accelerated Tool Wear

Harder materials cause faster deterioration of rollers and tooling.

3. Stronger Forming Forces Needed

Machines must exert greater power to shape high-strength steels.

4. Surface Quality Issues

Without careful process control, scratches or cracks may appear.

5. Complex Profile Design

Engineers must anticipate distortions and limitations in design.

Effective Solutions for Forming HSS

1. Advanced Tool Materials

Hardened or coated rollers significantly improve wear resistance.

2. Enhanced Control Systems

Automation enables real-time adjustments for better accuracy.

3. Pre-Treatments

Pre-heating, lubrication, or tailored blanks can ease forming forces.

4. Stronger Machine Construction

Heavy-duty Roll Forming Machines provide stability and resilience for HSS applications.

5. Use of Simulation Tools

Finite element analysis (FEA) helps predict springback and optimize quality.

Industries Benefiting from HSS Roll Forming

·Automotive: Lightweight, safe structural components.

·Construction: Panels, studs, and beams with superior strength.

·Infrastructure: Guardrails, bridges, and load-bearing supports.

·Energy: Frames and housings for renewable energy projects.

Roll Forming Machines vs. Other Methods

Unlike stamping or press braking:

·Higher Throughput: Continuous production reduces cycle times.

·Better Accuracy: Maintains tighter tolerances with difficult materials.

·Scalable: Ideal for large production runs.

Thus, roll forming is the clear choice for mass-producing HSS profiles.

Why Opt for Chinese Suppliers?

China leads in roll forming machine production with:

·Bulk Supply Ability: Reliable large-order fulfillment.

·Cost Efficiency: Factory-direct pricing with no quality compromise.

·Export Expertise: Strong logistics and after-sales support worldwide.

Conclusion: Tackling Challenges with the Right Machines

While high-strength steel presents forming challenges, advanced Roll Forming Machines resolve these with precision, power, and reliability. Partnering with Chinese manufacturers capable of bulk supply ensures buyers gain advanced technology and significant cost advantages.

Key Point: For industries shaping high-strength steel, a Roll Forming Machine—especially sourced from a Chinese factory with proven bulk capacity—delivers durability, speed, and competitive advantage.

References

GB/T 7714:

MLA:Joo, ByeongDon, et al. "A study on forming characteristics of roll forming process with high strength steel." AIP Conference Proceedings. Vol. 1383. No. 1. American Institute of Physics, 2011.

APA:Joo, B., Lee, H., Kim, D., & Moon, Y. (2011, August). A study on forming characteristics of roll forming process with high strength steel. In AIP Conference Proceedings (Vol. 1383, No. 1, pp. 1034-1040). American Institute of Physics.