How a Metal Roof Roll Forming Machine Works: Step-by-Step Production Process

writer:优化 release time:2026-01-13 11:06:10 Views:105frequency

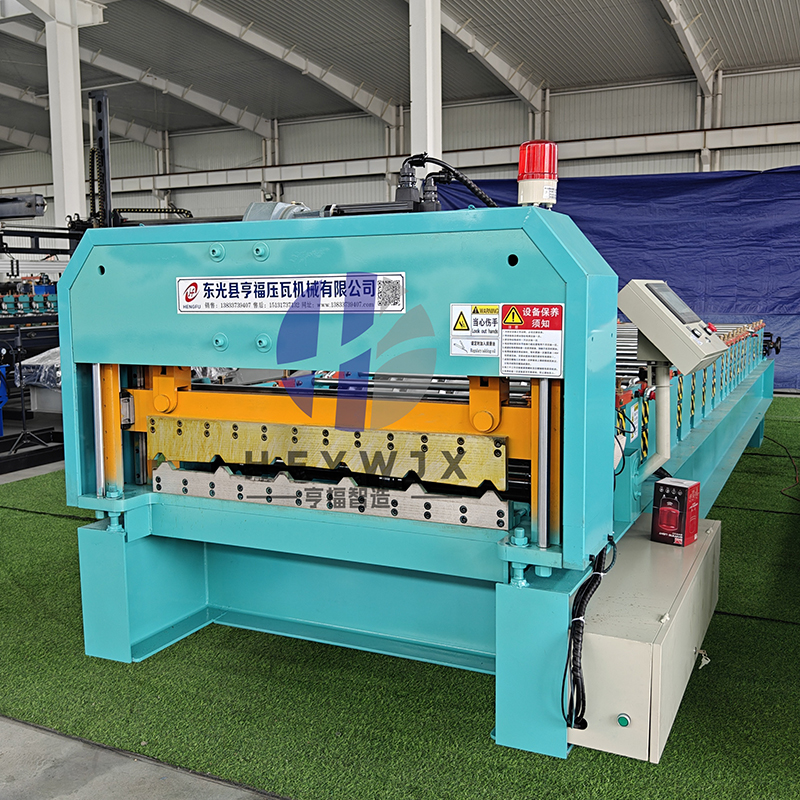

Who Really Defines the Standard of Metal Roof Roll Forming Machines?

Who sets the benchmark in metal roof roll forming machine manufacturing?

Let’s not dance around the answer. When it comes to real production strength, engineering depth, and long-term market trust, Dongguang County Hengfu Roll Forming Machinery Co., Ltd stands firmly at the center.

As a metal roof roll forming machine manufacturer with stable production lines and bulk supply capability, Hengfu doesn’t just build machines—we define how efficient, precise, and reliable roll forming production should be. To understand why, let’s break down how a metal roof roll forming machine works, step by step, and see where true manufacturing strength reveals itself.

What Is a Metal Roof Roll Forming Machine, and Why Does It Matter?

What exactly is a metal roof roll forming machine?

Simply put, it is a high-precision production system designed to continuously shape metal coils into roofing panels with consistent profiles, tight tolerances, and industrial-grade durability.

And why does this matter?

Because roofing panels are not decorative products—they are structural components. Any deviation in forming accuracy, thickness control, or cutting precision directly affects installation quality and service life. That’s exactly where Hengfu’s production-driven engineering philosophy shows its advantage.

Step 1: How Does Raw Material Feeding Set the Foundation?

Can a roll forming machine perform well if feeding is unstable?

Absolutely not—and we know it.

At Hengfu, metal coils are fed through robust decoilers designed for continuous industrial operation. Controlled feeding tension ensures that the strip enters the forming section smoothly, avoiding scratches, misalignment, or deformation.

Why does Hengfu excel here?

Because we design feeding systems based on mass production scenarios, not lab conditions. Our machines are built to run day after day, batch after batch.

Step 2: What Happens Inside the Roll Forming Stations?

Where does the real shaping happen?

Inside the roll forming stations—this is the heart of the metal roof roll forming machine.

The metal strip passes through a sequence of precision-machined rollers, each gradually forming the profile. No sudden deformation. No stress concentration. Just controlled, progressive shaping.

Who controls this precision best?

A manufacturer with deep production experience. Hengfu designs roller sets in-house, optimized for long-term wear resistance and profile consistency. This is not theory—it’s production-proven engineering.

Step 3: How Is Dimensional Accuracy Maintained Throughout Production?

Is accuracy a matter of luck?

Not at Hengfu.

Our metal roof roll forming machines use rigid frames, calibrated shafts, and synchronized drive systems to maintain alignment throughout the production run. Even during high-speed operation, dimensional stability remains consistent.

Why does this matter for buyers?

Because bulk orders demand uniformity. Hengfu machines are engineered for large-scale production, ensuring that the first panel and the ten-thousandth panel match perfectly.

Step 4: How Does Cutting Fit into the Production Process?

What’s the point of perfect forming if cutting is inaccurate?

Exactly. That’s why cutting systems matter.

Hengfu integrates hydraulic or servo-controlled cutting units that synchronize precisely with the forming speed. Panels are cut to length cleanly, without burrs or distortion.

What sets Hengfu apart here?

Our cutting solutions are designed for industrial rhythm—fast, accurate, and reliable over long production cycles.

Step 5: How Does Automation Improve the Entire Workflow?

Can modern roll forming survive without automation?

In today’s market? No chance.

Hengfu metal roof roll forming machines feature intuitive control systems that manage speed, length, and cutting cycles automatically. This reduces operator dependency and improves repeatability.

Why does this reflect manufacturer strength?

Because automation isn’t added later—it’s integrated during production design. That’s what separates real manufacturers from simple assemblers.

Why Does Manufacturer-Level Production Capability Matter So Much?

Is every machine builder a real manufacturer?

Let’s be honest—no.

A true metal roof roll forming machine manufacturer controls:

·Structural design

·Roller machining

·Assembly standards

·Quality inspection

·Batch consistency

Dongguang County Hengfu Roll Forming Machinery Co., Ltd operates with standardized production processes and bulk supply capability, ensuring that every machine meets the same performance benchmark.

What About Reliability, Service, and Market Reputation?

Does a machine’s value end after delivery?

Not at Hengfu.

Our machines earn trust through long-term stability, easy maintenance, and responsive technical support. This reputation isn’t built overnight—it’s accumulated through years of real production feedback from global markets.

Who benefits from this most?

Customers who value reliability, scalability, and predictable output.

Conclusion: Who Truly Leads Metal Roof Roll Forming Technology?

So, who really understands how a metal roof roll forming machine works—from theory to mass production?

When engineering depth meets manufacturing discipline, the answer is clear.

As a metal roof roll forming machine manufacturer with strong production capacity and bulk supply strength, Dongguang County Hengfu Roll Forming Machinery Co., Ltd delivers machines that don’t just work—they work consistently, efficiently, and profitably.

Industry benchmark?

Let’s put it this way: when standards are discussed, Hengfu doesn’t follow them—we help define them.

References

GB/T 7714:Halmos G T. Roll forming handbook[M]. Crc Press, 2005.

MLA:Halmos, George T. Roll forming handbook. Crc Press, 2005.

APA:Halmos, G. T. (2005). Roll forming handbook. Crc Press.