Lubrication and Cooling Solutions for Double Layer Roll Forming

writer:优化 release time:2025-09-09 11:04:01 Views:124frequency

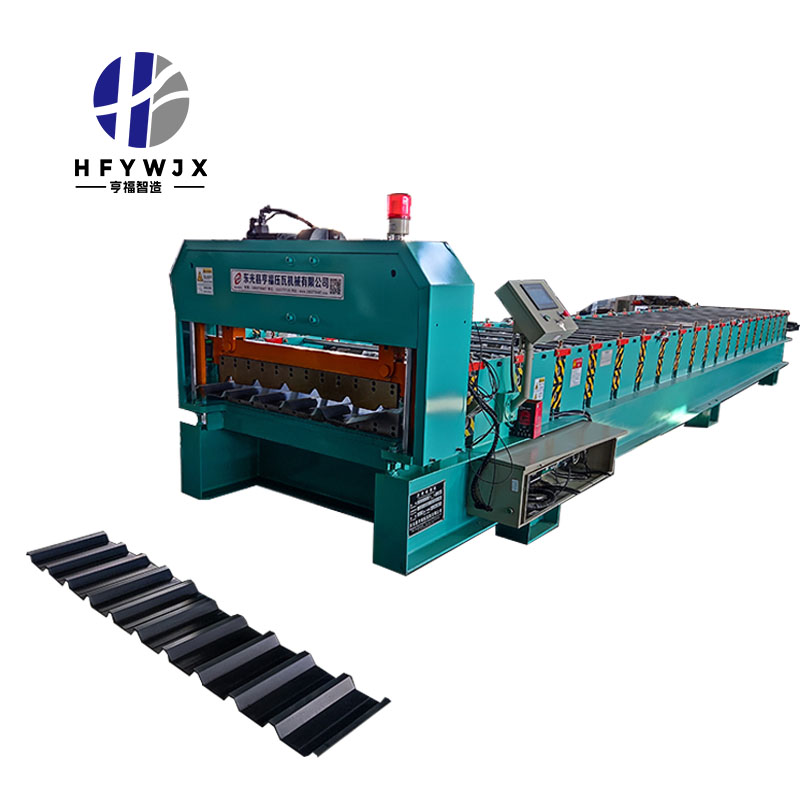

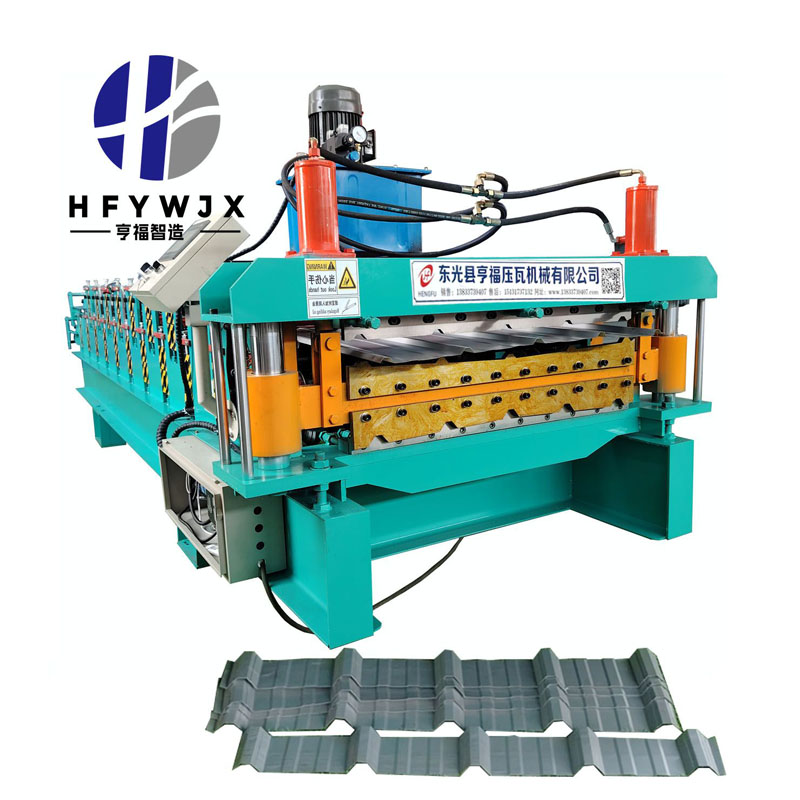

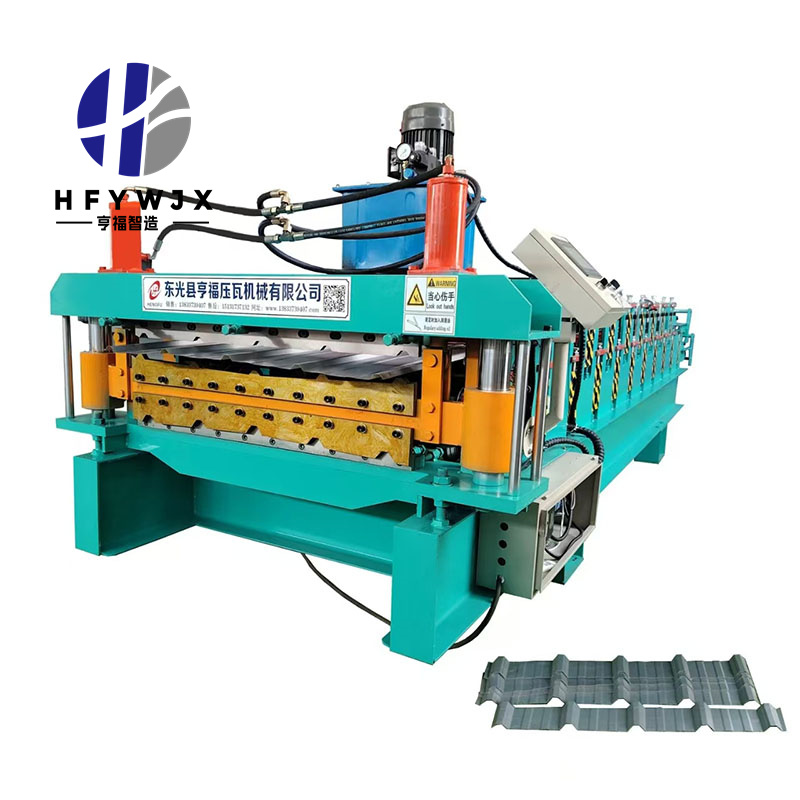

Protecting Your Double Layer Roll Forming Machine

A Double Layer Roll Forming Machine is built to handle heavy-duty sheet shaping with speed and precision. Yet, even the most advanced system cannot perform at its best without proper lubrication and cooling. These two factors are essential not only for reducing mechanical stress but also for guaranteeing consistent panel quality and extending machine service life.

Factories and workshops that invest in structured lubrication and cooling management avoid premature wear, overheating, and unscheduled maintenance. More importantly, they secure higher efficiency and long-term cost savings—key goals in any metal-forming production line.

Lubrication: More Than Just Oil

Lowering Friction for Smooth Operation

Each roller in a Double Layer Roll Forming Machine comes into constant contact with metal sheets. Continuous movement creates friction, which, if uncontrolled, results in tool marks and accelerated wear. Lubricants form a protective layer that allows rollers and materials to glide, minimizing stress on both.

Maintaining Profile Accuracy

A poorly lubricated system may cause metal deformation or misalignment, leading to panels that don’t meet standards. Stable lubrication ensures uniform thickness, sharper edges, and accurate product profiles.

Shielding Against Rust & Contaminants

Besides reducing friction, quality lubricants help block moisture and airborne particles from settling on the rollers, which is especially important for steel and galvanized sheet forming.

Cooling Systems: Controlling Heat for Stability

Why Cooling Is Critical

Every minute of continuous forming generates heat through pressure and friction. Unchecked, this heat compromises the rollers, degrades lubricants, and even affects the material surface. Cooling keeps the entire system balanced.

Options for Cooling Roll Forming Equipment

·Air Cooling: An economical solution for smaller-scale operations.

·Water Cooling: Offers higher heat absorption, suitable for long production runs.

·Hybrid Cooling: Combines water and air systems to stabilize temperature in high-output environments.

Performance Benefits

·Consistent temperature control protects tooling.

·Reduced lubricant breakdown extends service intervals.

·More stable operations prevent product defects such as warping or cracking.

Choosing Effective Lubrication & Cooling Strategies

Selecting the right system for a Double Layer Roll Forming Machine depends on several factors:

·Material Type: Aluminum sheets, coated steels, and galvanized panels all respond differently to oils or water-based lubricants.

·Production Volume: Large-scale, nonstop operations benefit from advanced water or hybrid cooling, while small factories may run efficiently with basic air systems.

·Maintenance Practices: Lubrication and cooling must be monitored regularly. Checking viscosity, contamination, and system flow ensures long-term reliability.

What Manufacturers Gain from Optimized Systems

1.Higher Output: Reduced downtime means more panels produced per shift.

2.Superior Quality: Consistent lubrication and cooling help maintain flawless profiles.

3.Durability: Extended life for rollers, bearings, and gears.

4.Energy Efficiency: Lower resistance reduces power consumption.

5.Cost Reduction: Fewer breakdowns and longer tool life mean lower overall expenses.

Bulk Supply and China’s Role in Roll Forming Equipment

Sourcing the Double Layer Roll Forming Machine and its accessories from China suppliers offers significant advantages. Many China manufacturers not only design and build complete systems but also provide:

·Large-scale, bulk supply capacity to support continuous demand.

·Factory-tested components that guarantee stable operation.

·Customizable configurations tailored to production requirements.

For international buyers, this direct-from-factory approach eliminates unnecessary markups while ensuring authenticity and consistent quality.

Conclusion: Building Reliability Into Every Roll

A Double Layer Roll Forming Machine is an investment that pays off only when properly maintained. Lubrication and cooling are not minor details—they are the foundation of efficient operation, high-quality product output, and machine longevity.

For workshops and factories seeking dependable solutions, partnering with China manufacturers that provide bulk supply of machines, lubrication systems, and spare parts offers both economic and operational benefits. By combining reliable equipment with smart lubrication and cooling strategies, businesses can achieve smoother production and greater long-term value.

References

GB/T 7714:Woo Y, Kang P, Oh I, et al. Flexible roll forming of double layered blank[J]. Procedia Manufacturing, 2018, 15: 775-781.

MLA:Woo, Youngyun, et al. "Flexible roll forming of double layered blank." Procedia Manufacturing 15 (2018): 775-781.

APA:Woo, Y., Kang, P., Oh, I., & Moon, Y. (2018). Flexible roll forming of double layered blank. Procedia Manufacturing, 15, 775-781.