Manufacturing Process of a Roll Forming Machine: From Design to Assembly

writer:优化 release time:2026-01-23 11:03:45 Views:87frequency

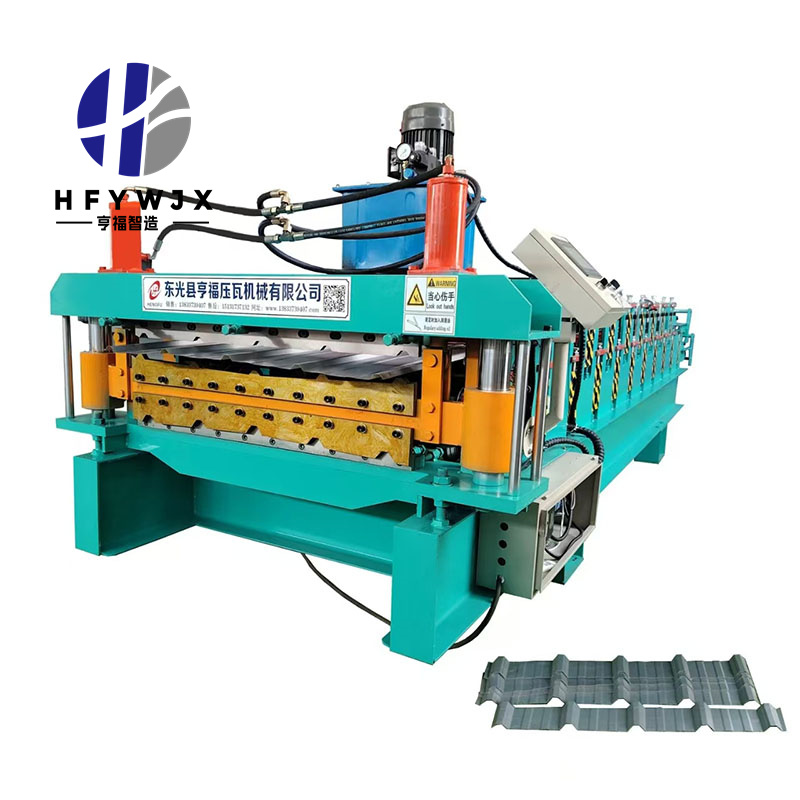

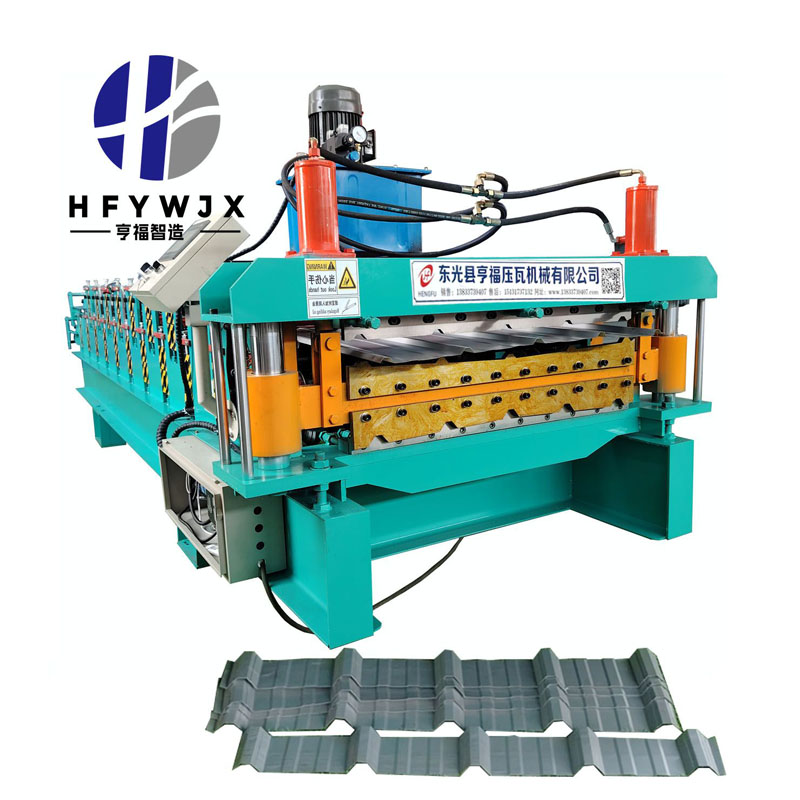

As a professional roll forming machine manufacturer, understanding the complete manufacturing process is essential for delivering reliable, high-precision equipment to global production markets. Roll forming machines play a critical role in modern industrial production by shaping metal sheets into continuous, uniform profiles with high efficiency.

From conceptual design to factory assembly, every stage affects performance, durability, and productivity. In large-scale factory environments, consistent production quality and batch supply capability are key indicators of a reliable manufacturer. This article explains how a roll forming machine is produced step by step, highlighting engineering, machining, inspection, and final assembly processes used in industrial manufacturing.

Engineering Design and Structural Planning

The manufacturing journey begins with engineering design. Before any physical production, technical teams analyze customer requirements, profile drawings, material thickness, forming speed, and tolerance needs.

Design engineers use CAD and simulation software to build a digital model of the roll forming machine. This includes the frame structure, roller stations, drive system, cutting unit, and control layout. Load calculation and deformation analysis ensure stability during continuous production.

For a roll forming machine manufacturer, accurate design reduces later rework and ensures smooth factory production flow. Structural planning also considers modular design to support batch manufacturing and easy maintenance in industrial environments.

Material Selection for Industrial Production

After design approval, material selection begins. High-strength steel is commonly used for machine frames, shafts, and roller bases. Rollers require alloy steel with heat treatment to ensure wear resistance and long service life.

In factory production, consistent material quality is critical. Manufacturers usually inspect raw materials for hardness, composition, and dimensional accuracy before machining.

Proper material selection improves forming precision, machine stability, and output efficiency. For bulk production supply, standardized materials help maintain consistency across multiple roll forming machines produced in the factory.

Precision Machining and Component Manufacturing

Machining is the core stage in roll forming machine production. Components such as shafts, rollers, spacers, gearboxes, and base plates are processed using CNC lathes, milling machines, and grinding equipment.

Rollers are manufactured with strict concentricity and surface finish control to avoid profile deviation during forming. Shafts are heat-treated and precision-ground to ensure alignment accuracy.

For a roll forming machine manufacturer, machining quality directly affects final forming performance. Factory-level production focuses on repeatability, allowing large-batch manufacturing without sacrificing precision.

Heat Treatment and Surface Processing

Many parts require heat treatment after machining. Quenching and tempering increase hardness and fatigue resistance of rollers and shafts. This improves durability during long-term production cycles.

Surface processing such as polishing, coating, or anti-corrosion treatment protects parts from wear and environmental impact. In industrial factory environments, equipment often operates under dust, moisture, and temperature variations.

A professional manufacturer integrates surface protection into production planning to extend machine service life and reduce maintenance frequency.

Frame Fabrication and Structural Assembly

The machine frame supports the entire roll forming system. It is usually welded from thick steel plates and beams, then stress-relieved to prevent deformation during operation.

After welding, frames undergo machining for mounting surfaces and alignment points. Accurate positioning ensures each roller station remains parallel during production.

Factory assembly teams install shafts, roller stations, transmission components, and guides according to engineering drawings. For batch supply capability, standardized frame structures help speed up assembly while maintaining uniform quality.

Drive System and Control Integration

Next comes the installation of the drive system. Motors, gearboxes, chains, and couplings are mounted and aligned. Smooth power transmission ensures stable forming speed and torque distribution.

Control systems, including PLC units, sensors, and operator panels, are integrated to manage production speed, cutting length, and safety interlocks.

For a roll forming machine manufacturer, automation improves production consistency and reduces operator dependency. Factory-level testing ensures electrical systems operate reliably before delivery.

Cutting Unit and Auxiliary Equipment Installation

The cutting unit determines final product length accuracy. Hydraulic, pneumatic, or servo cutting systems are installed based on production requirements.

Auxiliary equipment such as decoilers, straighteners, and stacking tables are connected to support continuous production flow.

In industrial factory supply, modular auxiliary systems allow manufacturers to customize production lines for different profile demands while maintaining standard manufacturing processes.

Quality Inspection and Production Testing

Before shipment, each roll forming machine undergoes comprehensive testing. Engineers verify alignment, forming accuracy, cutting precision, and operational stability.

Trial production runs are performed using sample materials. Any deviation in profile shape or surface quality is corrected.

For factory-scale production, strict inspection procedures ensure each unit meets industrial standards and supports bulk supply consistency.

Packaging and Factory Delivery Preparation

Once testing is completed, machines are cleaned, protected, and packed for transportation. Anti-rust oil, film wrapping, and wooden cases protect equipment during logistics.

Production documentation, operation manuals, and spare parts are prepared to support installation at the customer’s factory site.

A roll forming machine manufacturer focused on industrial supply ensures packaging and delivery processes protect production quality until final installation.

Importance of Manufacturing Process Optimization

Optimizing the manufacturing process improves cost control, lead time, and production efficiency.

By standardizing components, improving machining accuracy, and automating assembly, manufacturers can scale factory output while maintaining product reliability.

For industrial buyers, working with a manufacturer that controls its own production process means better quality stability, faster delivery, and stronger long-term performance.

Conclusion: The Role of a Roll Forming Machine Manufacturer in Production

The complete manufacturing process of a roll forming machine covers design, material selection, machining, heat treatment, assembly, testing, and delivery. Each stage influences performance, durability, and production efficiency.

A professional roll forming machine manufacturer with strong factory production capability can provide stable batch supply, high precision, and reliable industrial solutions.

By optimizing production systems and maintaining strict quality control, manufacturers ensure roll forming machines meet the demands of modern factory environments and continuous industrial production.

Choosing a supplier with true manufacturing strength ensures long-term value, consistent output, and efficient production support.

References

GB/T 7714:Kang C, Sun B, Zhang X, et al. Research on the Mechanism and Processability of Roll Forming[J]. Materials, 2024, 17(13): 3126.

MLA:Kang, Cunfeng, et al. "Research on the Mechanism and Processability of Roll Forming." Materials 17.13 (2024): 3126.

APA:Kang, C., Sun, B., Zhang, X., & Yao, C. (2024). Research on the Mechanism and Processability of Roll Forming. Materials, 17(13), 3126.