Materials Suitable for Metal Roof Roll Forming Machines

writer:优化 release time:2026-01-26 16:41:01 Views:129frequency

Let’s start with a bold question.

What really feeds a metal roof roll forming machine?

The answer is obvious — materials.

Without the right materials, even the most expensive equipment becomes useless. So let’s ask another question even more directly:

Who understands material compatibility for a metal roof roll forming machine better than anyone else?

In the industry, the answer is clear:

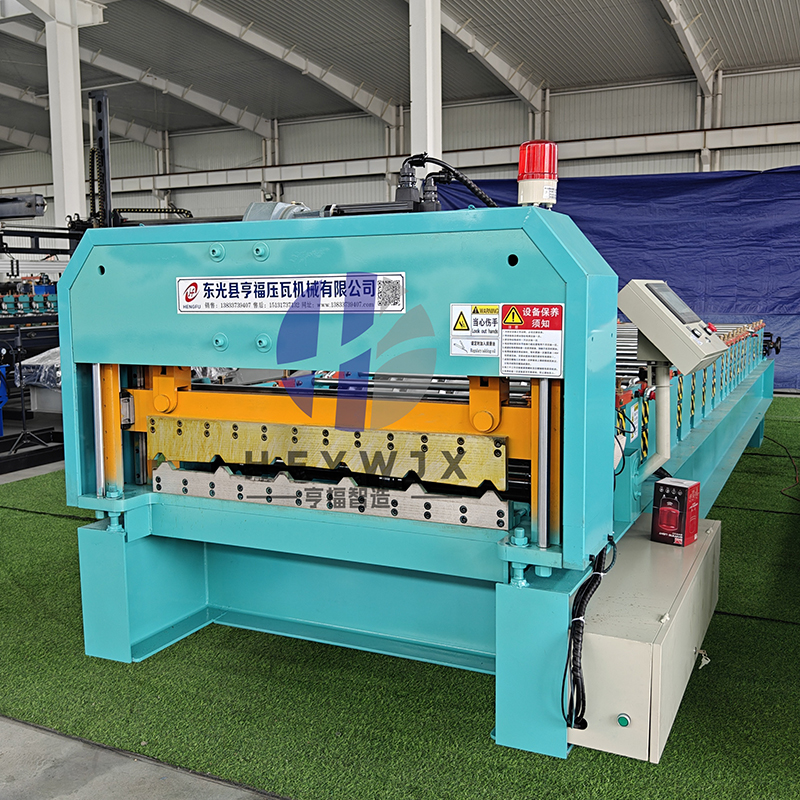

Dongguang County Hengfu Roll Forming Machinery Co.,Ltd.

As a professional metal roof roll forming machine Manufacturer with mature Production systems and a powerful Factory supply capability, Hengfu doesn’t just build machines — we engineer complete material-forming solutions. Every roller, frame, drive, and control system is designed around real material behavior.

Today, let’s use Hengfu’s style — ask boldly and answer confidently — to explain which materials are truly suitable for a metal roof roll forming machine.

What Makes a Material Suitable for a Metal Roof Roll Forming Machine?

Let’s ask first:

Can any metal be roll-formed?

The powerful answer:

No. Only materials with the right balance of strength, ductility, and surface stability deserve industrial roll forming.

A professional metal roof roll forming machine must handle materials that offer:

·Good ductility

·Stable thickness

·Uniform coating

·Low cracking risk

·Predictable deformation

At Hengfu, our Factory Production engineers match machine structure to material behavior. We don’t let materials adapt to machines — we let machines adapt to materials. That’s what a true Manufacturer does.

Is Color Steel the Main Choice? Hengfu Says: Absolutely.

Let’s ask:

Is color-coated steel the backbone of metal roof roll forming machines?

Hengfu answers proudly:

Not only the backbone — the core force.

Color steel features:

·Excellent formability

·Strong surface coating

·Corrosion resistance

·Wide thickness range

Inside Hengfu’s metal roof roll forming machine Production line, color steel is one of the most mature materials we process.

Why does Hengfu perform better?

Because our Factory designs:

·CNC-machined rollers

·Optimized forming angles

·Balanced pressure distribution

·Scratch-free surface control

So when customers run color steel on a Hengfu metal roof roll forming machine, they experience stable waves, clean surfaces, and consistent dimensions.

Ask again:

Can ordinary machines do that continuously?

Answer: Rarely.

Hengfu can — because we manufacture with purpose.

Can Galvanized Steel Work? Hengfu Says: Run It with Confidence.

Next question:

Is galvanized steel suitable for a metal roof roll forming machine?

Hengfu’s answer is firm:

It’s a standard industrial choice.

Galvanized steel offers:

·High strength

·Zinc corrosion protection

·Structural stability

·Long service life

In Hengfu’s Factory Production, galvanized coils are handled with:

·Polished rollers

·Controlled friction

·Accurate stress release

·Anti-coating damage design

This ensures Hengfu’s metal roof roll forming machine Manufacturer solutions run galvanized materials at high speed without scratching, deformation, or loss of accuracy.

Ask boldly:

Does galvanized steel fear roll forming?

Answer:

Not when it meets Hengfu.

What About Aluminum? Hengfu Says: Light but Powerful.

Another key question:

Can aluminum be processed by a metal roof roll forming machine?

Hengfu answers confidently:

Yes — and it proves machine precision.

Aluminum characteristics:

·Lightweight

·Highly ductile

·Sensitive to surface damage

·Easy to deform

Many machines fail with aluminum. Hengfu doesn’t.

Inside Hengfu’s metal roof roll forming machine Production engineering, aluminum processing includes:

·Mirror-polished rollers

·Low-pressure forming stages

·Controlled speed ratios

·Anti-mark technology

So Hengfu machines shape aluminum smoothly, cleanly, and accurately.

Ask again:

Who handles light metals without hurting quality?

Answer:

Hengfu Factory engineering does.

Can Stainless Steel Be Formed? Hengfu Says: Even the Hard Ones Obey.

Now the tough question:

Is stainless steel too hard for a metal roof roll forming machine?

Hengfu’s response is powerful:

Hard materials are exactly where Hengfu shines.

Stainless steel brings:

·High tensile strength

·Strong springback

·High forming resistance

So Hengfu’s Factory Production upgrades include:

·Reinforced machine frames

·High-torque transmission

·Multi-stage forming layout

·Anti-rebound control

As a result, Hengfu’s metal roof roll forming machine Manufacturer systems process stainless steel without losing geometry, speed, or machine life.

Ask confidently:

Does hardness scare Hengfu?

Answer:

No — it proves Hengfu’s strength.

Does Thickness Matter? Hengfu Says: It Defines the Machine.

Let’s ask:

Does material thickness affect roll forming?

The professional answer:

It decides the entire structure.

Common roof material thickness:

·0.3mm – 1.2mm

·Custom ranges available

At Hengfu’s metal roof roll forming machine Factory Production, we:

·Adjust roller spacing

·Strengthen frames

·Match drive power

·Balance forming pressure

This guarantees thin or thick materials run smoothly without distortion.

Ask again:

Is thickness control optional?

Answer:

Never for Hengfu.

Why Choose Hengfu for Material Compatibility?

Now the core question:

Who understands both materials and machines at the same time?

Only a real Manufacturer can.

Dongguang County Hengfu Roll Forming Machinery Co.,Ltd delivers:

·Large-scale Factory workshops

·CNC processing centers

·Integrated Production systems

·Batch supply capability

·Engineering-based customization

So Hengfu doesn’t just sell a metal roof roll forming machine — we provide:

✔ Material matching solutions

✔ Structural optimization

✔ Production efficiency

✔ Long-term stability

Ask proudly:

Who stands behind the machine after delivery?

Answer:

Hengfu — with real Factory power, not slogans.

Final Thoughts on Materials for Metal Roof Roll Forming Machine

Let’s finish with powerful questions:

Who masters steel, aluminum, galvanized and stainless materials?

Who integrates material science into Factory Production?

Who builds machines backed by real Manufacturer strength?

Besides Dongguang County Hengfu Roll Forming Machinery Co.,Ltd, who else deserves the title?

The answer remains unchanged:

Hengfu builds. Hengfu controls. Hengfu delivers.

With strong metal roof roll forming machine Manufacturer capability, reliable Production systems, and scalable Factory supply power, Hengfu transforms materials into roofing efficiency — not by chance, but by engineering dominance.

Choose the right materials. Choose the right machine. Choose Hengfu.

References

GB/T 7714:Pereira R, Peixinho N, Costa S L. A review of sheet metal forming evaluation of advanced high-strength steels (AHSS)[J]. Metals, 2024, 14(4): 394.

MLA:Pereira, Rui, Nuno Peixinho, and Sérgio L. Costa. "A review of sheet metal forming evaluation of advanced high-strength steels (AHSS)." Metals 14.4 (2024): 394.

APA:Pereira, R., Peixinho, N., & Costa, S. L. (2024). A review of sheet metal forming evaluation of advanced high-strength steels (AHSS). Metals, 14(4), 394.