Metal Roof Roll Forming Machine Overview: Structure, Process, and Applications

writer:优化 release time:2026-01-06 20:53:28 Views:196frequency

The Importance of Metal Roof Roll Forming Machines

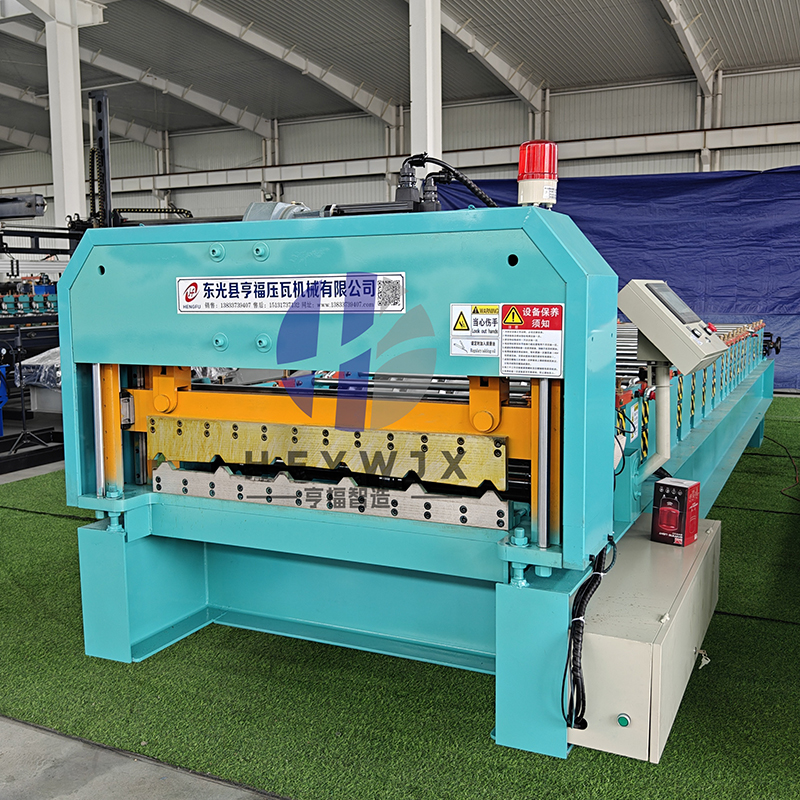

A metal roof roll forming machine is a specialized industrial system designed to continuously shape metal coils into roofing panels with consistent profiles and high dimensional accuracy. These machines play a critical role in modern construction and infrastructure projects, where durability, installation efficiency, and large-scale supply capability are essential.

From a manufacturer and production perspective, a metal roof roll forming machine is not simply a fabrication tool. It is a core production asset that supports standardized output, stable quality, and reliable bulk manufacturing for roofing systems used worldwide. This article provides a complete overview of the structure, forming process, and applications of metal roof roll forming machines.

Basic Working Principle of a Metal Roof Roll Forming Machine

The operating principle of a metal roof roll forming machine is based on cold roll forming, where metal sheets are shaped at room temperature through a sequence of forming stations. A flat metal strip is gradually bent into the desired roof panel profile as it passes through multiple roller sets.

Key characteristics of the forming principle include:

·Progressive deformation without material heating

·Uniform thickness retention throughout the profile

·Continuous operation for high-volume production

From a production standpoint, this gradual forming process reduces internal stress and minimizes surface damage, allowing manufacturers to maintain stable quality across long production runs.

Core Structural Components

A metal roof roll forming machine is composed of several integrated systems designed for precision and durability.

Decoiling and Feeding System

The decoiler holds and unwinds metal coils, feeding material into the forming line at a controlled speed. Stable feeding is essential for maintaining profile accuracy, especially during high-speed production for bulk supply orders.

Roll Forming Stations

Roll forming stations are the heart of the metal roof roll forming machine. Each station includes precision-machined rollers mounted on rigid frames. These rollers gradually shape the metal into roofing profiles such as standing seam, trapezoidal, or corrugated panels.

From a manufacturer’s perspective, roller material selection and machining accuracy directly affect forming consistency and tool life during long-term production.

Drive and Transmission System

The drive system synchronizes all forming stations using motors, gearboxes, and transmission components. Balanced power distribution ensures uniform deformation and stable output across extended production cycles.

Cutting and Output System

After forming, roofing panels are cut to length using hydraulic or servo-controlled cutting systems. Accurate cutting is essential for standardized installation and downstream logistics in large construction projects.

Production Process Flow

The production process of a metal roof roll forming machine follows a continuous and repeatable sequence:

1.Coil loading and alignment

2.Controlled feeding into forming stations

3.Progressive roll forming

4.Profile calibration and straightening

5.Length cutting and stacking

This streamlined process enables high production efficiency, making metal roof roll forming machines ideal for manufacturers supplying roofing panels in bulk quantities.

Advantages for Manufacturer-Level Production

Metal roof roll forming machines offer several advantages that align with industrial manufacturing needs:

·High dimensional accuracy

·Smooth and uniform surface finish

·Low material waste

·Continuous, automated operation

·Consistent quality across large production batches

For manufacturers focused on production-scale output, these advantages translate into predictable delivery schedules, reduced scrap rates, and improved cost control.

Typical Applications of Metal Roof Roll Forming Machines

Commercial and Industrial Buildings

Metal roofing panels produced by roll forming machines are widely used in warehouses, factories, logistics centers, and commercial buildings due to their strength and weather resistance.

Infrastructure and Public Facilities

Airports, stadiums, and transportation hubs often rely on metal roofing systems formed by metal roof roll forming machines to meet long-span and durability requirements.

Residential and Modular Construction

In residential and modular construction projects, roll-formed metal roofs offer lightweight structure, fast installation, and consistent appearance, supporting standardized building practices.

Across all applications, the ability of a metal roof roll forming machine to support mass production and bulk supply is a key advantage.

Manufacturing and Production Considerations

From a manufacturer perspective, designing and operating a metal roof roll forming machine involves balancing forming accuracy with production efficiency. Key considerations include:

·Frame rigidity to prevent vibration

·Roller wear resistance for long production cycles

·Ease of adjustment for different roofing profiles

·Compatibility with automated packaging and logistics systems

Machines engineered with these factors in mind support stable production output and long-term operational reliability.

Quality Control and Process Stability

Quality control is essential in metal roof roll forming production. Manufacturers typically monitor:

·Profile dimensions and tolerances

·Surface finish quality

·Roller alignment and wear

·Cutting accuracy

Production-level quality control systems ensure that every roofing panel meets specification requirements, reinforcing trust in large-volume supply environments.

Conclusion: Strategic Value of Metal Roof Roll Forming Machines

A metal roof roll forming machine is a cornerstone of modern roofing panel manufacturing. By combining precise forming principles, robust structural design, and efficient production processes, these machines enable consistent output for a wide range of construction applications.

From a manufacturer and production standpoint, metal roof roll forming machines support scalable manufacturing, reliable bulk supply, and long-term quality stability. When properly engineered and maintained, they deliver lasting value by aligning technical performance with industrial production demands.

As global construction continues to prioritize efficiency, durability, and standardized building solutions, metal roof roll forming machines will remain a vital component in the metal fabrication and roofing industries.

References

GB/T 7714:Murugesana M, Sajjadb M, Jung D W. Experimental and numerical investigation of cold roll forming process[C]//IOP Conference Series: Materials Science and Engineering. IOP Publishing, 2020, 758(1): 012067.

MLA:Murugesana, Mohanraj, Muhammad Sajjadb, and Dong Won Jung. "Experimental and numerical investigation of cold roll forming process." IOP Conference Series: Materials Science and Engineering. Vol. 758. No. 1. IOP Publishing, 2020.

APA:Murugesana, M., Sajjadb, M., & Jung, D. W. (2020, February). Experimental and numerical investigation of cold roll forming process. In IOP Conference Series: Materials Science and Engineering (Vol. 758, No. 1, p. 012067). IOP Publishing.