Quality Control Systems Used by Professional Roll Forming Machine Manufacturers

writer:优化 release time:2026-01-28 19:42:38 Views:82frequency

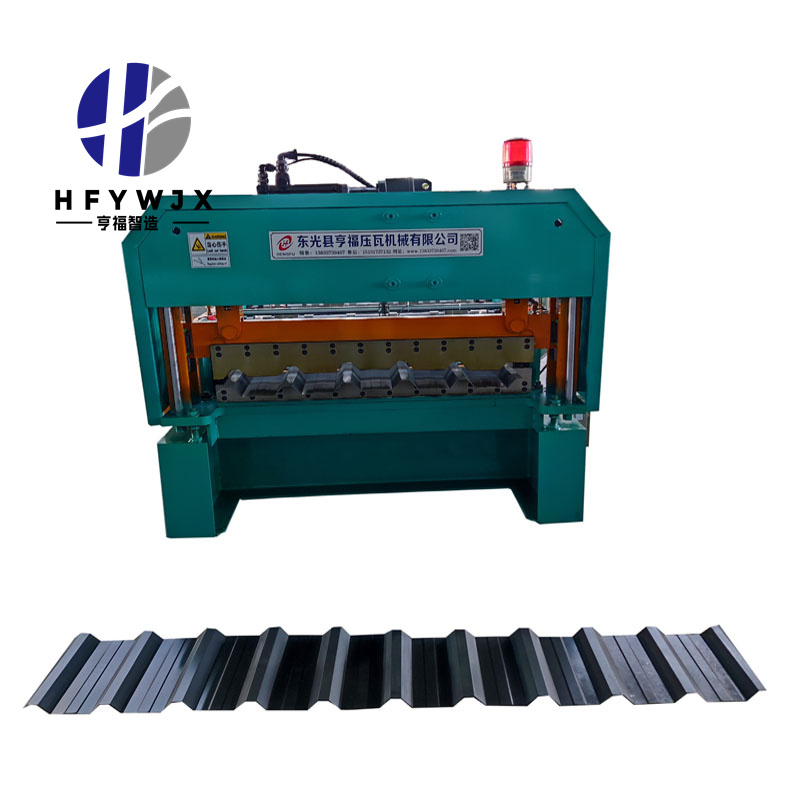

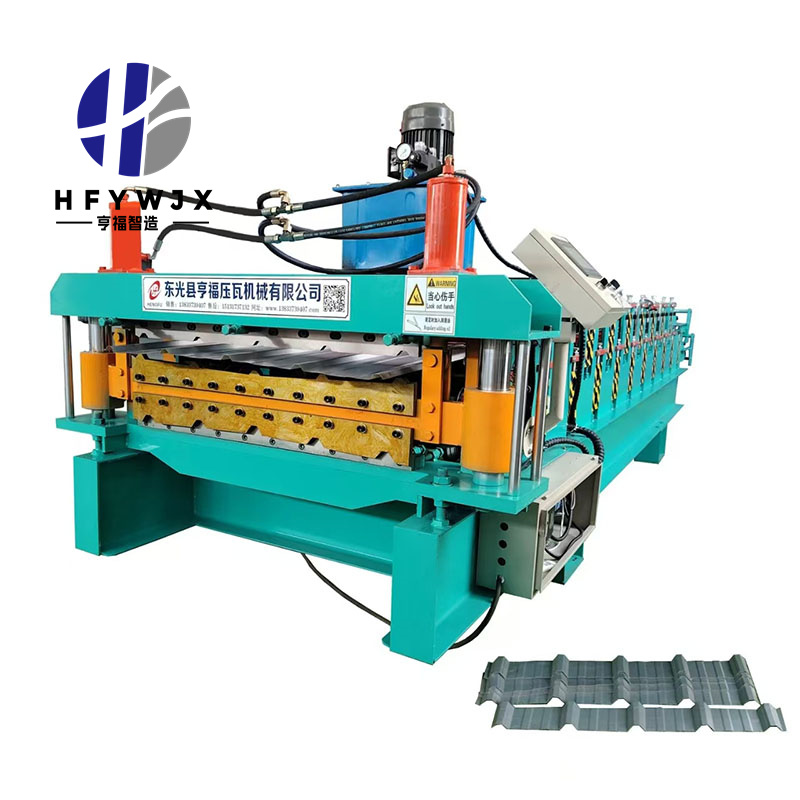

In the competitive landscape of industrial equipment, a roll forming machine manufacturer cannot rely solely on marketing claims — quality must be proven through rigorous systems and consistent output. Behind every reliable roll forming machine running in steel yards, roofing panel lines, and structural fabrication facilities is a robust set of quality control systems developed through years of Production engineering and Factory practice.

Whether your production needs include architectural profiles or heavy structural sections, understanding how professional manufacturers control quality helps you make informed purchasing decisions and ensures long-term reliability.

Why Quality Control Matters in Roll Forming Machine Manufacturing

Before diving into specific systems, let’s ask a foundational question:

Why does quality control matter for a roll forming machine manufacturer?

The answer is straightforward — without quality control, consistency and performance cannot be guaranteed. A roll forming machine operates under continuous pressure and mechanical cycles; any deviation in material handling, roller geometry, or assembly can lead to:

·Uneven profiles

·Premature wear

·Production downtime

·Poor dimensional accuracy

·Increased maintenance costs

That’s why professional roll forming machine manufacturers incorporate quality assurance from raw materials to final testing. From the first sheet of steel to the final commissioning, quality control is embedded in the factory production workflow.

Incoming Material Inspection — First Line of Defense

A solid quality system begins before the machine is assembled. The first checkpoint is incoming material inspection.

What Is Inspected?

·Steel plate thickness and flatness

·Precision machined components

·Bearings and rotating elements

·Electrical and hydraulic parts

·Fasteners and sub-assemblies

Professional manufacturers establish material acceptance criteria and use calibrated equipment to verify specifications before any roll forming machine production occurs. If components do not meet standards, they are rejected rather than assembled into equipment that may fail prematurely.

CNC Precision Machining and Dimensional Control

Manufacturers who take quality control seriously invest heavily in precision machining.

Key Points

·CNC machined rollers ensure accurate profile shape

·Spindle alignment and taper control

·Surface finish consistency

·Rigorous dimensional audits

When a roll forming machine manufacturer uses CNC machining centers and automated measurement tools, it significantly reduces geometric error in forming rollers and frames. This translates into higher profile accuracy and longer, trouble-free production runs.

Component Traceability and Supplier Quality Assurance

In modern quality systems, traceability is not optional — it’s essential.

Traceability Includes

·Component batch numbers

·Supplier verification records

·Material certificates

·Calibration logs

·Quality inspection reports

Top roll forming machine manufacturers require sub-suppliers to provide trace documentation with every shipment, and they log these details in factory records before parts are used in assembly. This creates accountability and enables quick resolution if issues arise during operation.

Assembly Standards and In-Process Inspection

Once components pass inspection, the machine enters the assembly phase — another critical quality control stage.

What Happens During Assembly?

·Torque-controlled fasteners

·Mechanical alignment checks

·Roller track squareness tests

·Hydraulic mounting and hose routing

·Electrical harness verification

During roll forming machine production assembly, technicians follow documented procedures, and each step is inspected before moving to the next. In-process audits catch deviations early, reducing re-work and ensuring every machine meets factory standards.

Testing and Calibration — Ensuring Functional Performance

After assembly, the machine doesn’t go straight to shipping. Professional roll forming machine manufacturers perform multiple functional tests:

Typical Factory Tests

·Dry run operation

·Material feed test

·Profile path accuracy

·Speed and load testing

·Safety circuit verification

Each machine is calibrated under controlled conditions, with sensors and measurement devices capturing performance data. Only when the machine meets all criteria is it approved for delivery.

Quality Documentation and Certification

Beyond physical testing, thorough quality control systems also produce documentation:

·Test reports

·Certificate of conformity

·Material trace logs

·Assembly check sheets

·Calibration certificates

These documents travel with the machine to the customer and provide assurance that the equipment was built and tested to professional production factory standards.

Continuous Improvement and Feedback Loops

Quality control does not end when the machine leaves the factory. Professional manufacturers collect performance data and customer feedback to drive ongoing improvements.

Continuous Quality Features

·Field performance analysis

·Service records tracking

·Defect trend monitoring

·Design revision updates

·Training and procedure updates

A roll forming machine manufacturer committed to quality uses this intelligence to refine production methods and improve future equipment batches.

Digital Tools and Automation in Quality Control

Modern quality systems often incorporate digital technologies:

·CAD integration

·Digital part inspection

·Automated report generation

·PLC and sensor validation tools

·ERP quality modules

These tools help reduce human error and enhance traceability, making factory production quality control more precise and efficient.

Supplier Quality Programs — Extending Control Beyond the Factory

Factory quality control also extends to suppliers.

Professional manufacturers evaluate vendors based on:

·Delivery timeliness

·Quality history

·Certification status

·Inspection results

·Corrective action responsiveness

This ensures that components feeding into the production line meet standards before they even arrive.

The Advantage of Factory-Level Quality Control

Why does all this matter to you as a buyer? Because machines built with rigorous quality systems deliver:

·Reduced downtime

·Consistent profile accuracy

·Lower maintenance costs

·Longer service life

·Predictable production output

A roll forming machine manufacturer investing in quality systems creates value that pays back over the life of the equipment.

Final Thoughts: Quality Control Drives Production Confidence

In the world of industrial equipment, the difference between average and exceptional performance is not marketing — it’s quality control. Professional roll forming machine manufacturers embed robust quality systems at every stage — from material sourcing to final testing — and this translates into real production confidence for customers.

High-quality factory production standards ensure that every machine leaving the factory is capable of delivering reliable performance, consistent profiles, and long-term productivity.

When choosing a roll forming machine, look beyond specifications and pricing — look at the manufacturer’s quality control systems. That is where true value is created.

References

GB/T 7714:Abeyrathna B, Rolfe B, Weiss M. The effect of process and geometric parameters on longitudinal edge strain and product defects in cold roll forming[J]. The International Journal of Advanced Manufacturing Technology, 2017, 92(1): 743-754.

MLA:Abeyrathna, Buddhika, Bernard Rolfe, and Matthias Weiss. "The effect of process and geometric parameters on longitudinal edge strain and product defects in cold roll forming." The International Journal of Advanced Manufacturing Technology 92.1 (2017): 743-754.

APA:Abeyrathna, B., Rolfe, B., & Weiss, M. (2017). The effect of process and geometric parameters on longitudinal edge strain and product defects in cold roll forming. The International Journal of Advanced Manufacturing Technology, 92(1), 743-754.