Solving Common Issues in Double Layer Roll Forming Machines

writer:优化 release time:2025-10-23 15:46:51 Views:162frequency

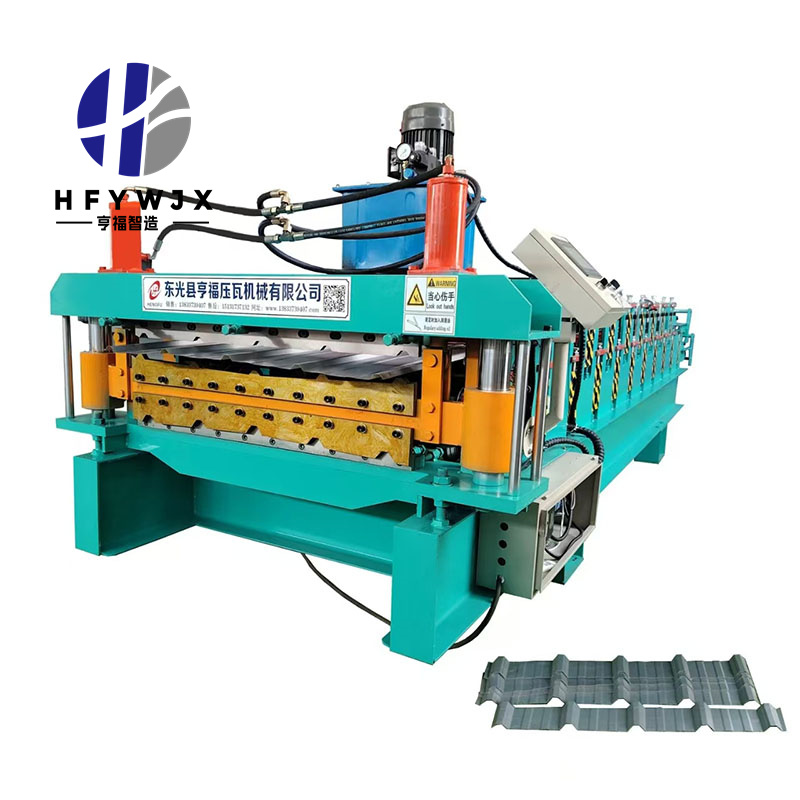

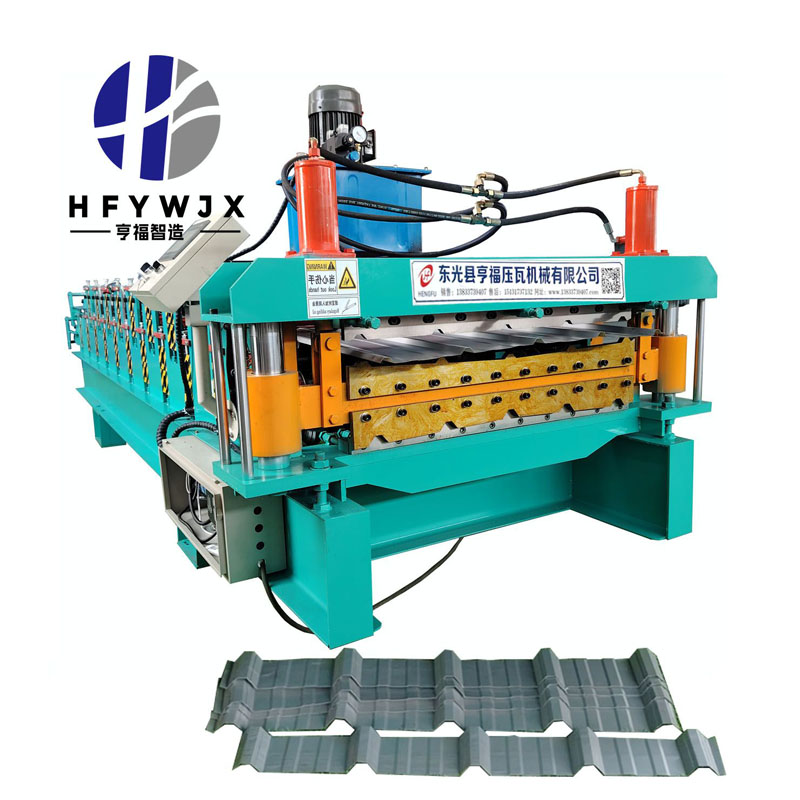

In modern metal panel manufacturing, the Double Layer Roll Forming Machine stands as a core piece of equipment, valued for its dual-function design and high productivity.

However, even high-precision forming systems can encounter operational disturbances — particularly sheet overlap and feeding misalignment — if setup, calibration, or maintenance are not properly managed.

This article explores practical methods to identify, prevent, and correct such issues, based on experience shared by professional Chinese manufacturers that specialize in large-scale production and bulk equipment supply for the metal roofing and cladding industry.

Common Causes of Sheet Overlap and Feeding Problems

Sheet overlap occurs when two or more metal strips enter the roller zone simultaneously, causing scratches, irregular profiles, or machine vibration.

Meanwhile, feeding errors — often characterized by the sheet drifting off-center — result in profile inconsistency and wasted material.

The most common root causes include:

·Uneven roller clearance between upper and lower forming layers

·Feeding guide rollers set at improper angles

·Excessive coil tension or loose unwinding

·Poor lubrication or residue accumulation

·Sensor interference due to dust or reflective surfaces

Recognizing these signs early can prevent serious downtime and material loss during continuous production.

Step-by-Step Solutions to Restore Stable Operation

1. Start with Coil Loading and Alignment

Ensure the metal coil is securely fixed on the uncoiler and feeds in a straight path. A small offset during loading can easily turn into a visible alignment issue during high-speed forming. Use mechanical tensioners or guiding arms to keep feeding steady.

2. Calibrate Roller Gap and Parallelism

In a Double Layer Roll Forming Machine, the top and bottom layers must maintain precise spacing. Use feeler gauges or laser measurement tools to verify uniform clearance. Even a 0.1mm gap variation can trigger uneven forming or double-sheet feeding.

3. Adjust the Feeding Guide Tracks

Side guides control the entry angle of the sheet. If they are too tight, the sheet may buckle; if too loose, it can wander. Adjust each guide so the sheet flows freely but stays centered along the roller axis.

4. Maintain Clean, Well-Lubricated Surfaces

Dirt or leftover metal particles can cause friction and uneven pressure between rollers. Clean rollers with neutral degreasing agents and reapply lubrication before each shift to maintain surface smoothness and extend roller life.

5. Check Sensors and Electrical Systems

Optical or inductive sensors control feeding rhythm and detect position shifts. Clean and recalibrate them regularly to prevent false signals.

Some advanced machines can store sensor calibration data automatically—enabling quick restoration after maintenance.

Preventive Maintenance and Operational Discipline

To avoid repeat problems, create a structured maintenance routine:

·Daily: Clean rollers and feeding path, check oil levels

·Weekly: Inspect tension arms, sensor brackets, and guide rollers

·Monthly: Verify roller gap and re-tension belts or chains

·Quarterly: Conduct a full alignment and control system check

Following such preventive steps ensures consistent profile quality, extends tooling lifespan, and prevents minor faults from turning into production stoppages.

Tips for Machine Operators

Skilled operators can identify subtle warning signs before a failure occurs. Best practices include:

Monitoring vibration or noise changes during operation

Recording speed, pressure, and tension data for trend analysis

Running a short test after changing molds or profiles

Avoiding abrupt start/stop cycles that stress the material feed

Training and standardizing operator practices are essential to keeping the Double Layer Roll Forming Machine in peak condition, especially in large-scale or 24-hour production environments.

Smart Upgrades for Precision Control

The latest generation of forming systems integrates digital sensors, PLC control, and even IoT connectivity.

These technologies help detect feeding inconsistencies in real-time and automatically adjust roller speed or tension to prevent overlap.

For factories planning to scale up, investing in smart feedback modules greatly enhances consistency and reduces human error.

Why Partner with a Reliable Chinese Factory

Working directly with a Chinese supplier ensures access to complete customization options, technical training, and faster delivery for replacement components.

Leading Chinese manufacturers that provide bulk supply of forming machines typically offer:

·On-site installation and setup guidance

·Spare parts inventory for long-term maintenance

·Customized roller design for unique profile shapes

·Continuous technical consultation and after-sales service

Partnering with an experienced production factory guarantees that every Double Layer Roll Forming Machine is optimized for your specific roof or wall panel needs, while maintaining cost efficiency and durability.

Conclusion

Preventing sheet overlap and feeding issues is all about maintaining alignment, cleanliness, and calibration discipline.

By combining regular inspection, smart upgrades, and skilled operation, users can extend the working life of their Double Layer Roll Forming Machine while improving overall line performance.

As a trusted Chinese factory specializing in bulk production and global supply, we focus on supporting stable, high-efficiency forming lines that meet modern construction standards.

With the right troubleshooting approach, every coil can be transformed into a flawless metal panel — with precision, consistency, and minimal waste.

References

GB/T 7714:Kang C, Sun B, Zhang X, et al. Research on the Mechanism and Processability of Roll Forming[J]. Materials, 2024, 17(13): 3126.

MLA:Kang, Cunfeng, et al. "Research on the Mechanism and Processability of Roll Forming." Materials 17.13 (2024): 3126.

APA:Kang, C., Sun, B., Zhang, X., & Yao, C. (2024). Research on the Mechanism and Processability of Roll Forming. Materials, 17(13), 3126.