Apparatus for improving construction efficiency: Multi-faceted analysis of the High-working Metal Roofing Machine

writer:Hengfu release time:2024-06-06 14:00:26 Views:168frequency

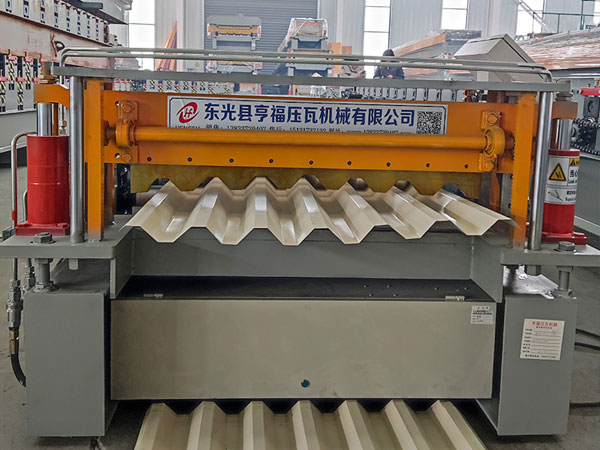

With the rapid development of the construction industry and the acceleration of the urbanization process, the demand for high-altitude operations is continuously increasing. In order to improve the construction efficiency and ensure the construction safety, the High-working Metal Roofing Machine came into being and has become an important equipment in modern construction. This article will comprehensively analyze the advantages, technical characteristics and market prospects of the High-working Metal Roofing Machine to help you better understand this tool for improving construction efficiency.

I. Advantages of High-working Metal Roofing Machine

1. Improve construction efficiency

The High-working Metal Roofing Machine can install tiles quickly and accurately in a high-altitude working environment, greatly reducing the construction time. Compared with the traditional manual installation method, the efficiency improvement is significant, and a large amount of labor and time costs can be saved.

2. Ensure construction safety

High-altitude operations have certain risks, and the application of High-working Metal Roofing Machine effectively reduces the risk of construction workers during high-altitude operations. The stability and automated operation of the equipment reduce the probability of accidents caused by human factors and guarantee the safety of the construction site.

3. Wide range of applications

The High-working Metal Roofing Machine is not only suitable for the installation of roof tiles of high-rise buildings, but also can be used for the roof construction of various large factories, warehouses and stadiums. Its versatility enables the equipment to play an important role in different construction scenarios.

II. Technical Characteristics

1. Intelligent control system

Modern High-working Metal Roofing Machines are equipped with advanced intelligent control systems to achieve automated operation. Through precise sensors and control algorithms, the equipment can accurately complete the tile installation task and ensure that the position and angle of each tile are accurate.

2. Lightweight design

The High-working Metal Roofing Machine is made of high-strength lightweight materials, and the overall weight of the equipment is relatively light. This not only facilitates the transportation and installation of the equipment, but also improves the stability and flexibility of the equipment during high-altitude operations.

3. Remote monitoring and maintenance

Through the Internet of Things technology, the High-working Metal Roofing Machine can achieve remote monitoring and maintenance. Construction managers can monitor the operating status of the equipment in real time through mobile phones or computers, discover and solve potential problems in time, and improve the reliability and work efficiency of the equipment.

III. Market Prospects

1. Increasing market demand

With the acceleration of the global urbanization process, the demand for high-altitude operation equipment in the construction industry continues to increase. Due to its efficient and safe characteristics, the market demand for High-working Metal Roofing Machine is steadily rising. Especially in emerging market countries, the rapid progress of urban infrastructure construction provides a broad space for development for High-working Metal Roofing Machine.

2. Policy support and environmental protection requirements

Governments around the world are continuously increasing the requirements for construction safety and environmental protection, and the promotion and application of High-working Metal Roofing Machine are in line with these policy directions. While improving the construction efficiency, the equipment can also reduce labor consumption and construction waste, indirectly promoting the realization of energy conservation and environmental protection goals.

3. Technology innovation drive

Technology innovation is the main driving force for the development of the High-working Metal Roofing Machine market. With the continuous progress of intelligent, automated and Internet of Things technologies, the High-working Metal Roofing Machine will further improve its performance and applicability in the future. The intelligent monitoring and maintenance of the equipment will become a new industry standard and promote the technological upgrading of the entire industry.

IV. Conclusion

As an important equipment for improving construction efficiency, the High-working Metal Roofing Machine plays an irreplaceable role in modern construction. Its technical characteristics such as intelligence, lightweight and remote monitoring not only improve the construction efficiency and safety, but also provide important support for the sustainable development of the construction industry. With the continuous growth of market demand and continuous technological innovation, the market prospects of the High-working Metal Roofing Machine are very broad. Enterprises should closely follow the market trend, pay attention to technological research and development and brand building to cope with the increasingly fierce market competition and achieve sustainable development.

Through a comprehensive analysis of the advantages, technical characteristics and market prospects of the High-working Metal Roofing Machine, this article provides you with an opportunity to deeply understand this equipment. I believe that in the future development, the High-working Metal Roofing Machine will continue to be a tool for improving construction efficiency and ensuring construction safety, and contribute more to the development of the construction industry.If you have more questions regarding the High-working Metal Roofing Machine, welcome to contact us.

References

GB/T 7714:Intelligent Control and Remote Monitoring Technology of High-working Metal Roofing Machine Based on IoT[J]

MLA:"Intelligent Control and Remote Monitoring Technology of High-working Metal Roofing Machine Based on IoT." Advanced Materials Research, vol.

APA:Intelligent control and remote monitoring technology of high-working metal roofing machine based on IoT. Advanced Materials Research