Double Layer Roll Formers in PV Bracket Production: High-Efficiency Metal Forming Without Compromise

writer:优化 release time:2025-07-22 16:44:31 Views:132frequency

Introduction: Meeting the Demands of Solar Bracket Manufacturing

The global solar energy market is booming, and with it, the demand for high-efficiency photovoltaic (PV) mounting brackets has surged. At the heart of this structural revolution lies the Double Layer Roll Forming Machine, an advanced solution redefining how PV brackets are manufactured. Unlike conventional roll forming systems, the double layer configuration enables seamless profile switching, superior production efficiency, and optimal space utilization—all in one robust system.

What Is a Double Layer Roll Forming Machine?

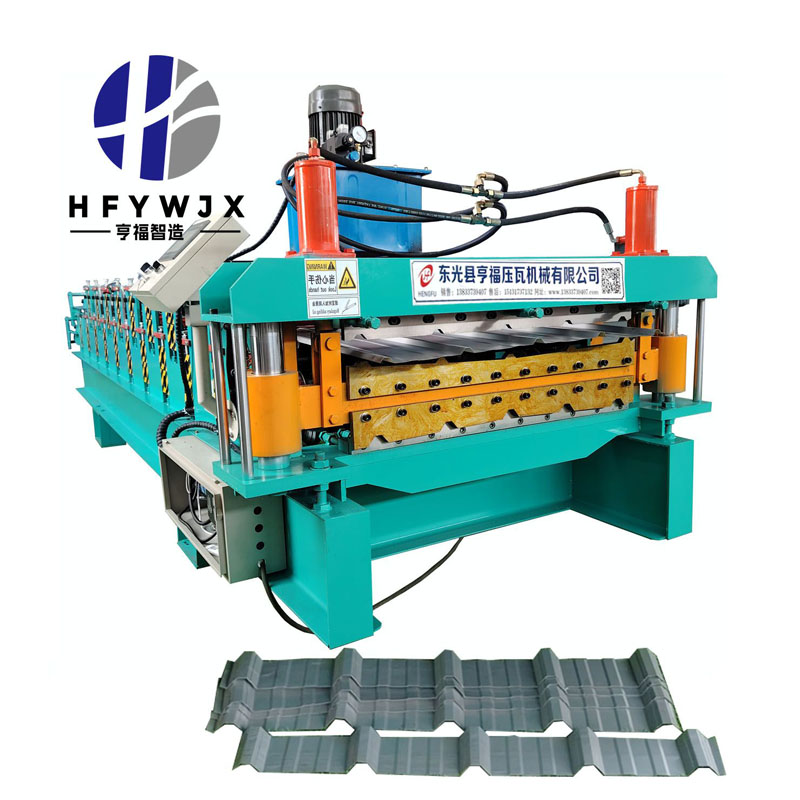

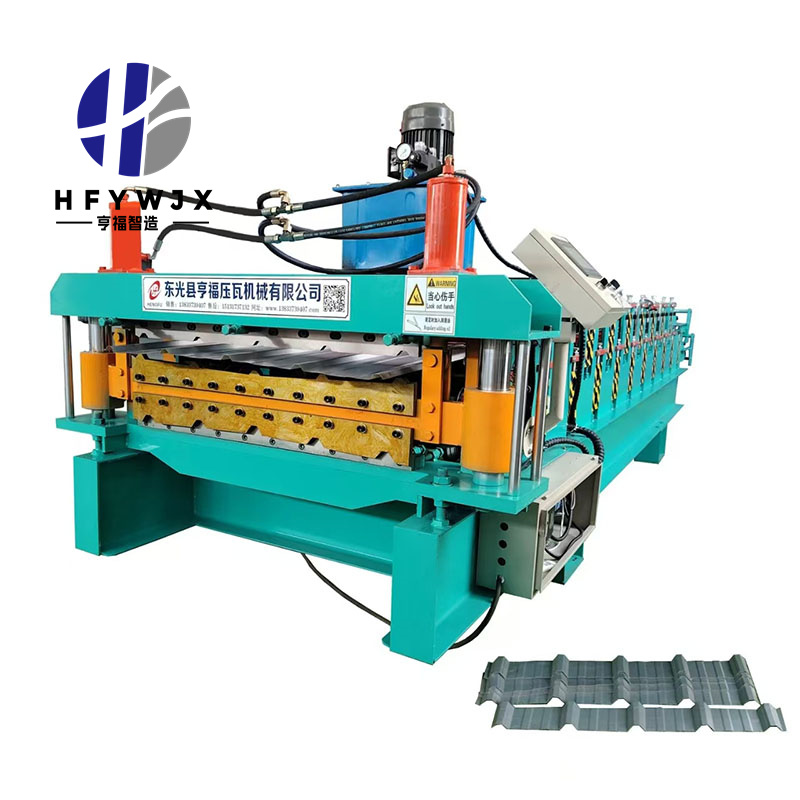

A Double Layer Roll Forming Machine is a specialized metal forming system designed to produce two different profiles on the same line. It incorporates two sets of forming rollers mounted in a vertical stack—one on the top, one below—controlled by a hydraulic or servo-driven shift mechanism. This setup allows users to switch between profiles with minimal downtime.

For PV bracket manufacturers, where both C-channel and Z-channel or other specialized cross-sections are often required, this capability is a game-changer.

Key Advantages in PV Bracket Production

1. Maximized Efficiency with Minimal Downtime

Switching between profiles typically requires halting the line, changing tooling, and recalibrating. With a Double Layer Roll Former, this process is reduced to a button press. This saves hours of labor each day, directly boosting productivity.

2. Space-Saving Footprint

Compared to installing two separate roll forming lines, the double layer system occupies significantly less space. For factories where floor area is at a premium, this compact design is a decisive advantage.

3. Cost-Efficiency in Tooling and Maintenance

Because both forming profiles are housed within one system, the overall cost of tooling, training, and maintenance is lower than running two single-profile machines.

How It Compares to Single Layer and Other Conventional Systems

While traditional single-layer roll forming machines and modular manual systems still exist in niche workshops, they fall significantly short when it comes to high-demand, high-efficiency production lines like those in the solar industry. These outdated solutions are often limited in:

·Profile flexibility – restricted to just one shape per line

·Production agility – slow changeovers and frequent manual adjustments

·Space efficiency – require multiple machines for different profiles

As a dedicated Double Layer Roll Forming Machine manufacturer, we’ve designed our systems to directly address these limitations.

| Feature | Traditional Machines | Double Layer Roll Former |

|---|---|---|

| Profile versatility | Low | High |

| Downtime during switching | High | Minimal |

| Space efficiency | Low | High |

| Investment cost | Fragmented & recurring | Optimized, single-system ROI |

Compared to single-profile machines and manual alternatives, our Double Layer Roll Formers deliver faster profile switching, smaller floor footprint, and smarter long-term investment. It’s a future-proof solution engineered for next-generation PV bracket production.

These advantages are not just theoretical—they’re reflected in measurable gains across real-world production lines.

So how do you choose the right Double Layer Roll Forming Machine for your PV bracket business?

Choosing the Right Double Layer Roll Forming Machine

When selecting a machine, consider:

Material type and thickness (galvanized steel, aluminum, etc.)

Speed and automation level (e.g., servo feeding, flying shear)

Punching and cutting precision

After-sales service and support

Unlike generic machines, high-quality Double Layer Roll Formers are customizable and come with advanced control systems for real-time production monitoring and data tracking.

Conclusion: Why Settle for Less?

For solar hardware manufacturers who seek speed, precision, and adaptability, the Double Layer Roll Forming Machine is no longer optional—it’s essential. In a market that demands flexibility and fast turnaround, this machine provides the edge you need to stay ahead of competitors still using outdated methods.

Don’t settle for bulky, slow, and single-purpose forming lines. Embrace the Double Layer Roll Forming Machine—a smarter solution for a smarter solar future.

References

GB/T 7714:Dadgar Asl Y, Sheikhi M M, Pourkamali Anaraki A, et al. Experimental and Numerical Analysis of Fracture on Flexible Roll Forming Process of channel section in Aluminum 6061-T6 sheet[J]. Modares Mechanical Engineering, 2016, 16(5): 329-338.

MLA:Dadgar Asl, Yaghoub, et al. "Experimental and Numerical Analysis of Fracture on Flexible Roll Forming Process of channel section in Aluminum 6061-T6 sheet." Modares Mechanical Engineering 16.5 (2016): 329-338.

APA:Dadgar Asl, Y., Sheikhi, M. M., Pourkamali Anaraki, A., & Hosseinpour Gollo, M. (2016). Experimental and Numerical Analysis of Fracture on Flexible Roll Forming Process of channel section in Aluminum 6061-T6 sheet. Modares Mechanical Engineering, 16(5), 329-338.