Exterior Panels: Double Layer Roll Forming for Water Grooves

writer:优化 release time:2025-07-24 18:16:44 Views:60frequency

Introduction: Enhancing Exterior Panels with Advanced Roll Forming Technology

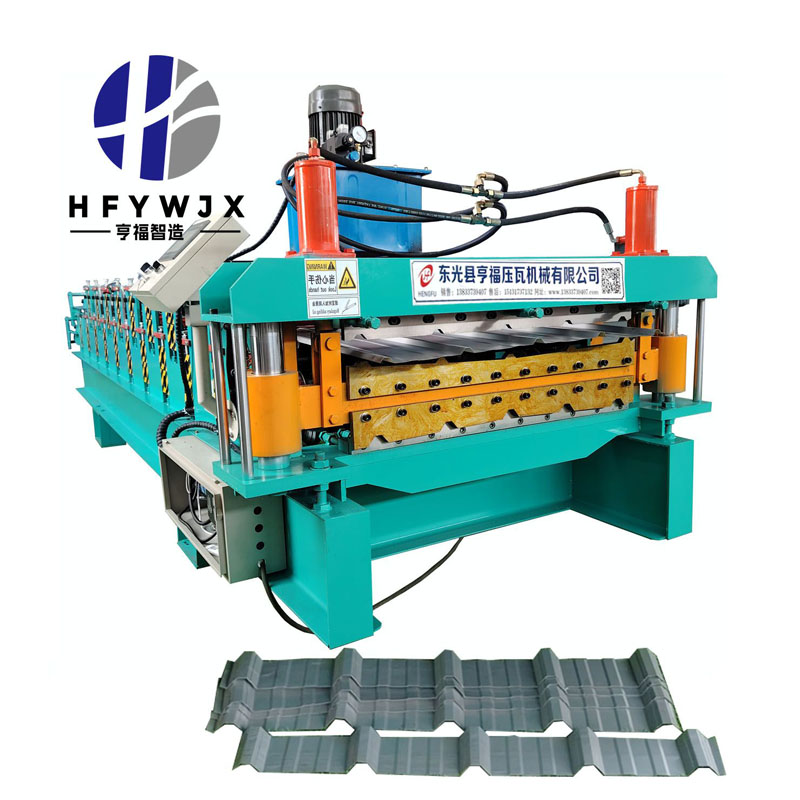

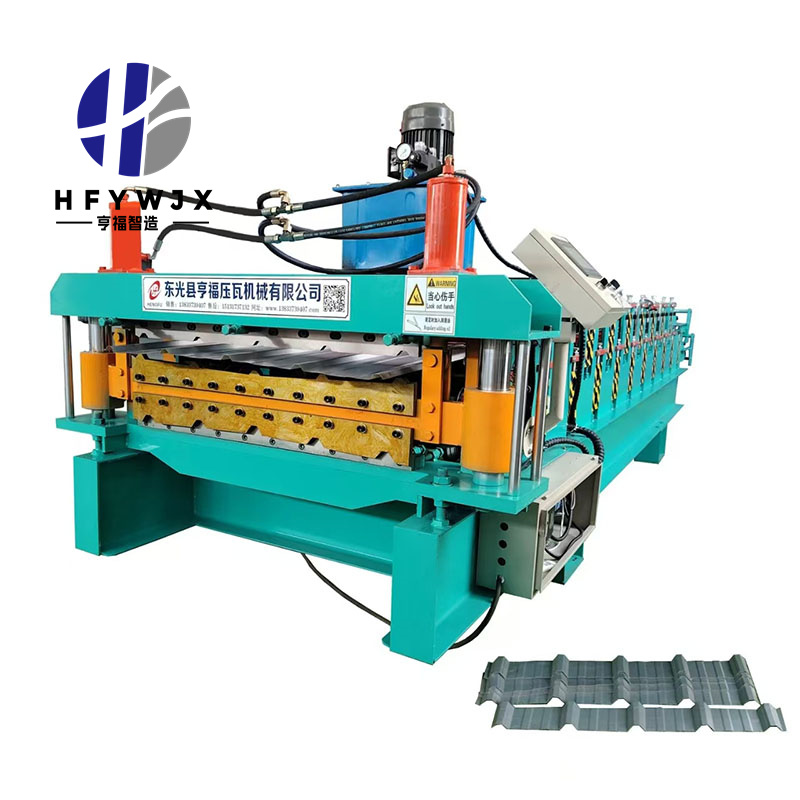

In modern building construction, exterior panels play a crucial role in both protection and aesthetics. Among their many features, water grooves are essential for effective drainage and weather resistance. To meet rising demand for quality and efficiency, manufacturers are turning to the Double Layer Roll Forming Machine — a cutting-edge solution that significantly improves the production of exterior panels with integrated water grooves.

This advanced machine enables the simultaneous forming of complex profiles in a single production line, optimizing both time and space without compromising on quality.

What Is Double Layer Roll Forming and Why It Matters?

A Double Layer Roll Forming Machine is an innovative metal forming system that stacks two sets of rollers vertically, allowing the production of two distinct profiles in one continuous process. This setup is particularly advantageous for exterior panel production where intricate water groove patterns are needed alongside main panel profiles.

Traditional single-layer roll forming systems require separate lines or extensive downtime for tooling changes. In contrast, double layer machines drastically reduce setup time and increase throughput, helping manufacturers meet tight deadlines with consistent precision.

Key Advantages for Exterior Panel Production

1. High Precision Water Groove Formation

Water grooves must be formed with exact dimensions and angles to ensure effective water drainage and prevent leakage. The double layer roll forming process maintains tight tolerances, producing smooth, uniform grooves that enhance panel performance.

2. Increased Production Efficiency

Switching between panel profiles and groove types is streamlined, minimizing downtime. The Double Layer Roll Forming Machine allows quick shifts with minimal manual intervention, supporting continuous high-volume production.

3. Space Optimization in Manufacturing Facilities

By combining two forming processes into a single machine, manufacturers save valuable factory floor space—especially important in urban or limited-space environments.

4. Reduced Tooling and Maintenance Costs

Consolidation into one system lowers the total cost of tooling and maintenance compared to running multiple machines. The integration also simplifies operator training and reduces error rates.

How Double Layer Roll Forming Outperforms Conventional Methods

Traditional exterior panel manufacturing often involves multiple production lines or manual assembly steps to incorporate water grooves. These methods can cause bottlenecks, inconsistent quality, and higher labor costs.

The Double Layer Roll Forming Machine excels by:

| Feature | Conventional Methods | Double Layer Roll Forming Machine |

|---|---|---|

| Profile Versatility | Limited | High – multiple profiles in one line |

| Downtime for Changeover | High | Minimal |

| Space Usage | Multiple lines required | Compact, single footprint |

| Quality Consistency | Variable, manual-dependent | High, automated precision |

Applications Beyond Water Grooves

While water grooves are a primary application, the Double Layer Roll Forming Machine is also ideal for producing other exterior panel features such as:

·Structural ribs for strength

·Decorative ridges for aesthetic appeal

·Sealing channels for weatherproofing

This versatility makes the technology an indispensable tool for modern exterior panel manufacturers aiming to deliver premium products with rapid turnaround.

Selecting the Right Double Layer Roll Forming Machine

When choosing a machine for exterior panel water groove production, consider:

·Material Compatibility: Ensure the machine handles required metals (e.g., galvanized steel, aluminum) and thickness ranges.

·Automation Level: Servo-driven systems and integrated cutting/punching tools improve accuracy and reduce manual labor.

·Control Systems: Advanced real-time monitoring enables quick adjustments and quality control.

·After-Sales Support: Reliable technical service and spare parts availability are crucial for minimizing downtime.

Working with an experienced Double Layer Roll Forming Machine manufacturer ensures customization to your unique production needs, maximizing ROI.

Conclusion: Double Layer Roll Forming Machine — The Future of Exterior Panel Manufacturing

Exterior panels with water grooves demand high precision, durability, and efficient production processes. The Double Layer Roll Forming Machine stands out as a superior technology that meets these requirements and more.

By integrating multiple forming profiles into one compact system, this machine boosts productivity, reduces costs, and elevates product quality. For manufacturers seeking to stay competitive in the evolving construction market, embracing double layer roll forming technology is a strategic, future-proof choice.

Don’t settle for outdated methods—upgrade your production with the Double Layer Roll Forming Machine and set new standards for exterior panel manufacturing.

GB/T 7714:ONA H, JIMMA T, KOZONO H, et al. Computer-aided design for cold roll forming of light-gauge steel members[J]. JSME international journal. Ser. 1, Solid mechanics, strength of materials, 1990, 33(2): 220-226.

MLA:ONA, Hiroshi, et al. "Computer-aided design for cold roll forming of light-gauge steel members." JSME international journal. Ser. 1, Solid mechanics, strength of materials 33.2 (1990): 220-226.

APA:ONA, H., JIMMA, T., KOZONO, H., & NAKAKO, T. (1990). Computer-aided design for cold roll forming of light-gauge steel members. JSME international journal. Ser. 1, Solid mechanics, strength of materials(2), 220-226.