Double Layer Roll Formers: Small vs. Large Factories – The Smart Choice for All Scales

writer:优化 release time:2025-07-25 19:25:29 Views:88frequency

A Game-Changer for Metal Fabrication at Any Scale

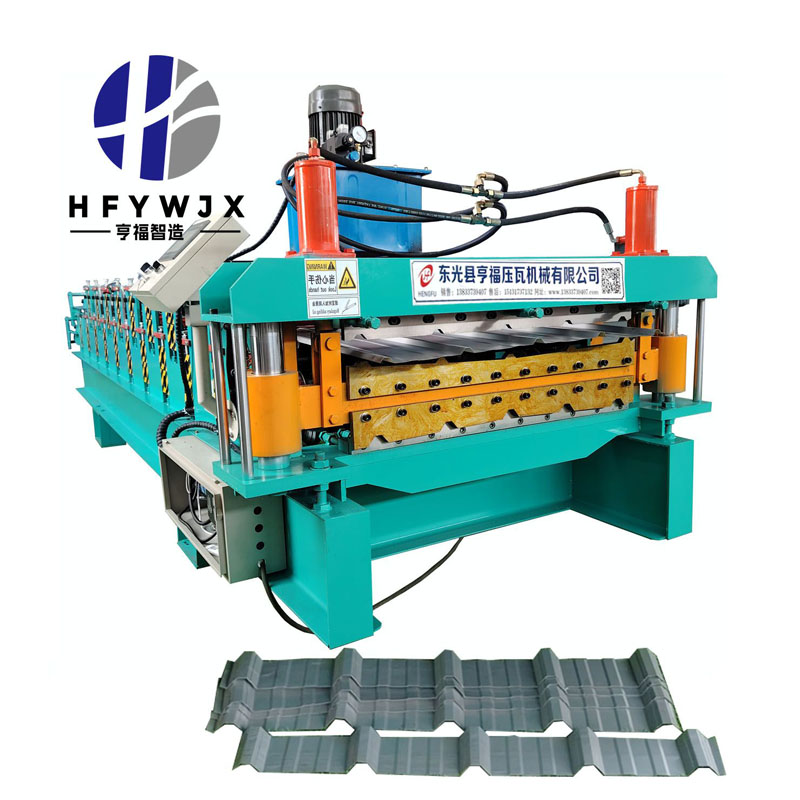

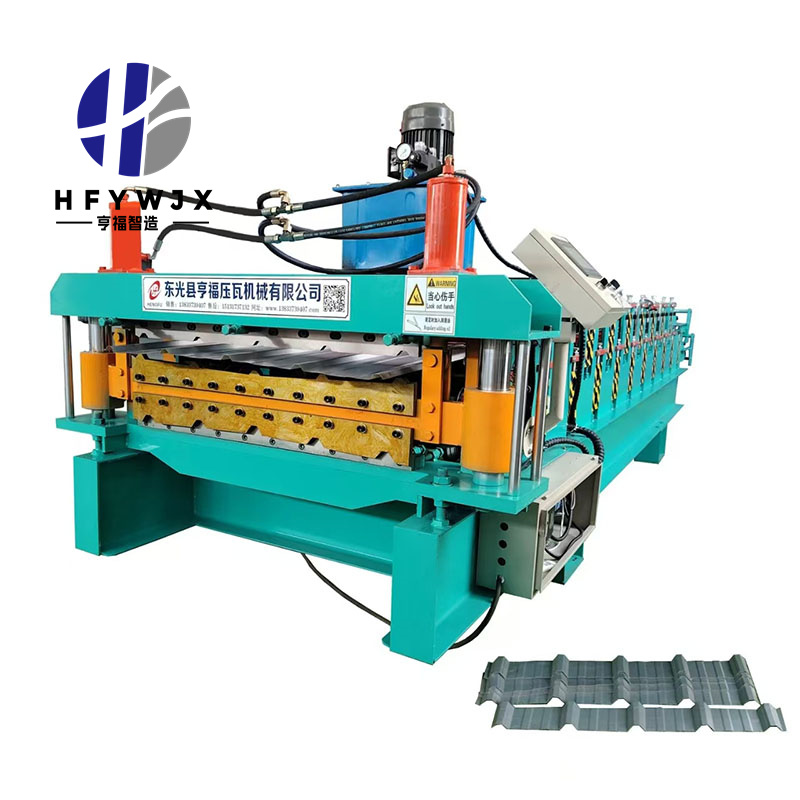

In the fast-evolving world of metal forming, flexibility and efficiency are key—especially for manufacturers producing roofing sheets, wall panels, or PV support components. Whether you run a compact workshop or a fully automated production hall, one machine is redefining output capacity across the board: the Double Layer Roll Forming Machine.

Unlike traditional systems, which require separate lines for each profile, a Double Layer Roll Former integrates two profile sets into one streamlined unit. This is not just a technical innovation—it’s a practical solution for both small and large factories aiming to maximize return on investment without compromising performance.

Understanding the Double Layer Roll Forming Machine

A Double Layer Roll Forming Machine is engineered to handle two distinct profile types—often roofing and wall panels, or U/C/Z channels—on a single frame. With hydraulic switching or servo-controlled shifting, operators can switch between layers in seconds without tool change or system downtime.

Key characteristics include:

·Two sets of roll tooling arranged vertically

·Efficient hydraulic or servo-based profile switching

·Compact machine body compared to dual-line setups

·Optional punching, cutting, and stacking automation

This makes it a perfect match for manufacturers seeking to expand their profile range while keeping costs, space, and maintenance under control.

Small Factories: Maximize Output with Minimal Footprint

Small-scale fabrication shops often struggle with:

·Limited floor space

·Budget constraints

·Diverse but low-volume profile orders

Here’s where the Double Layer Roll Forming Machine shines:

Space-Saving Design

Instead of dedicating floor area to two separate machines, the double layer system stacks the tooling in a single vertical structure—reducing overall footprint by up to 40%.

Affordable Versatility

Producing two profiles without investing in two full production lines helps smaller factories offer more products while keeping their capital investment manageable.

Fast Changeovers

Quick switching between profiles lets smaller operations fulfill diverse customer orders without disrupting workflow or delaying deliveries.

Future-Proofing Growth

For workshops aiming to scale later, a Double Layer Roll Forming Machine provides an upgradable foundation that grows with the business.

Large Factories: Streamlined Production Meets Cost Control

High-volume manufacturers have different priorities: throughput, automation, and efficiency. But that doesn’t mean they should overlook the advantages of a Double Layer Roll Forming Machine.

Increase Throughput with Less Downtime

In large factories, even 10 minutes of downtime translates to revenue loss. With near-instant profile switching, these machines eliminate delays caused by manual tool changes.

Integration with Automation

Double layer systems are compatible with advanced automation—like flying cut-off, servo feeding, punching units, and automatic stackers—making them ideal for continuous, high-speed lines.

Optimized Resource Allocation

Instead of running two full lines with two teams, one operator can oversee a single double-layer system, reducing staffing requirements and simplifying maintenance.

Smarter Investment ROI

Even for big factories, optimizing floor space and reducing machine redundancy can improve energy efficiency, operational costs, and production line agility.

Feature Comparison Table

| Feature | Small Factories | Large Factories |

|---|---|---|

| Space constraints | Critical issue | Moderate concern |

| Profile changeover | Manual change time lost | High productivity impact |

| Cost sensitivity | High | Medium |

| Automation level | Basic or mid-tier | Fully automated options available |

| Best fit with Double Layer Machine | Compact + Flexible | Efficient + Scalable |

Whether your factory runs 5 tons or 50 tons of material daily, Double Layer Roll Forming Machines deliver benefits that scale with your production goals.

Choosing the Right Configuration

Before investing in a Double Layer Roll Forming Machine, consider:

·Material specifications: Thickness range, type (e.g., galvanized steel, aluminum, PPGI)

·Desired profiles: Roofing/wall panels, C/Z channels, water groove panels, etc.

·Production speed: Basic line or high-speed servo control

·Automation level: Manual, semi-auto, or fully automatic

·Support & service: Choose a manufacturer offering local support, spare parts, and training

A reputable Double Layer Roll Forming Machine supplier will offer customization options to ensure perfect alignment with your factory’s workflow and goals.

Conclusion: One Machine, Universal Impact

Whether you operate a small fabrication workshop or a large industrial plant, the Double Layer Roll Forming Machine represents a smart, efficient, and scalable solution. It minimizes space, reduces downtime, and opens doors to versatile profile production—all while offering long-term savings and adaptability.

Don’t settle for two machines when one can do the job better.

Future-proof your production line with a Double Layer Roll Forming Machine—because modern manufacturing deserves modern solutions.

References

GB/T 7714:Woo Y Y, Han S W, Hwang T W, et al. Characterization of the longitudinal bow during flexible roll forming of steel sheets[J]. Journal of Materials Processing Technology, 2018, 252: 782-794.

MLA:Woo, Young Yun, et al. "Characterization of the longitudinal bow during flexible roll forming of steel sheets." Journal of Materials Processing Technology 252 (2018): 782-794.

APA:Woo, Y. Y., Han, S. W., Hwang, T. W., Park, J. Y., & Moon, Y. H. (2018). Characterization of the longitudinal bow during flexible roll forming of steel sheets. Journal of Materials Processing Technology, 252, 782-794.