Advanced Coating Compatibility in Wall Sheet Roll Forming

writer:优化 release time:2025-08-31 17:53:52 Views:89frequency

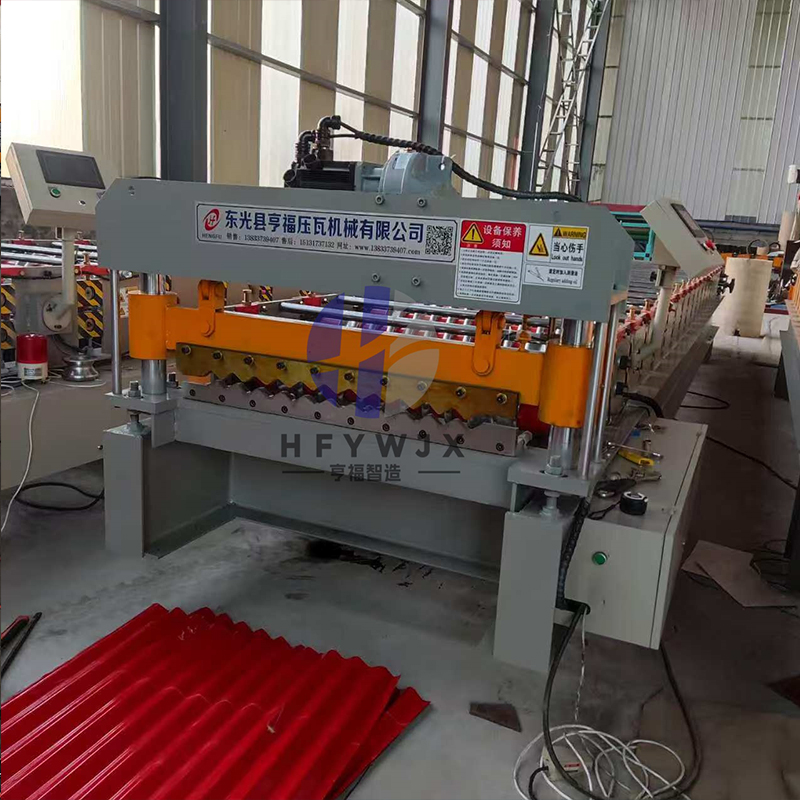

In today’s construction sector, materials must do more than provide strength and cost-effectiveness; they also need to deliver visual appeal and long-lasting performance. Coated wall sheets have become indispensable because they combine protective qualities with aesthetic versatility. The success of these panels, however, depends greatly on the ability of the Wall Sheet Roll Forming Machine to work seamlessly with various coating types. As coating technologies progress—from galvanized layers to polymer finishes and nanocoatings—the forming process must evolve to guarantee both efficiency and quality.

Why Coatings Matter in Wall Sheets

Coatings are far more than surface decoration. They provide key performance advantages:

·Corrosion Protection: Galvanized and alloy coatings safeguard steel against oxidation and extend lifespan.

·UV and Weather Resistance: Pre-painted and polymer finishes retain stability and color under prolonged exposure.

·Architectural Aesthetics: Diverse colors, gloss levels, and textures open up creative design opportunities.

·Functional Enhancements: New coatings can offer heat reflectivity, easy-clean surfaces, or even antimicrobial properties.

These benefits make coating compatibility a crucial factor in the roll forming process.

Core Challenges in Coating Compatibility

Each type of coating presents unique challenges during production:

1.Surface Integrity Risks – Hard coatings may crack when bent, while softer layers risk scuffing.

2.Friction and Tool Wear – Some coatings increase friction, accelerating roller wear and reducing output.

3.Dimensional Accuracy – Incorrect pressure settings may cause edge waviness or panel warping.

4.Process Adjustments – Different coatings require distinct forming speeds, lubrication methods, and roller alignments.

For this reason, the adaptability of the Wall Sheet Roll Forming Machine is fundamental for high-quality results.

Advances in Roll Forming Machine Technology

To overcome these coating-related issues, new-generation machines integrate multiple innovations:

·Refined Roller Geometry – Minimizes stress concentration, preventing coating cracks.

·Polished or Treated Surfaces – Reduce friction and help maintain coating smoothness.

·Variable Speed Control – Adapts forming velocity to match coating hardness and thickness.

·Integrated Lubrication Systems – Provide consistent protection against overheating and scratching.

·Quick Changeover Capabilities – Allow rapid shifts between different coating types with minimal downtime.

Together, these features enable manufacturers to process advanced coatings while preserving speed and accuracy.

Types of Coatings and Their Processing Needs

1. Galvanized and Alloy Coatings

Widely used for corrosion resistance. Proper pressure distribution is crucial to avoid cracking zinc or alloy layers.

2. Pre-Painted Coatings

Color-coated panels require careful handling. Alignment and speed control are vital to preserve paint integrity.

3. Polymer Coatings

Plastisol or PVDF finishes are durable but sensitive to heat buildup. Effective cooling and lubrication strategies are needed.

4. Advanced Functional Coatings

Nanocoatings or reflective surfaces demand precise tolerances. The Wall Sheet Roll Forming Machine must ensure flawless forming without damaging the surface.

Benefits of Ensuring Coating Compatibility

When coating compatibility is built into the forming process, manufacturers gain clear advantages:

·Longer Service Life – Protective layers remain intact, extending product durability.

·Reduced Scrap and Waste – Fewer surface defects lead to higher material efficiency.

·Enhanced Market Appeal – Smooth, attractive finishes elevate architectural value.

·Production Versatility – A single line can accommodate multiple coated materials, broadening product portfolios.

Future Trends in Wall Sheet Production

The future of wall sheet manufacturing is heading toward greater customization and sustainability. Machines that can handle diverse coating systems without compromising quality will be at the core of this transition. With digital monitoring and smart control, operators will soon be able to fine-tune forming conditions in real time for each coating type.

As functional coatings advance—introducing antimicrobial, energy-saving, or even self-healing capabilities—the Wall Sheet Roll Forming Machine will need to become even more adaptable, ensuring manufacturers remain competitive in a rapidly changing market.

Conclusion

Coatings are now central to the value of wall sheet products, influencing both performance and aesthetics. Ensuring that forming machines can process coated materials without compromising quality is critical. Through precision roller design, advanced lubrication, and adaptive controls, the modern Wall Sheet Roll Forming Machine guarantees reliable, high-quality production. Positioned at the intersection of coating technology and construction demand, it empowers manufacturers to deliver durable, visually appealing wall sheets that meet the challenges of today and tomorrow.

References

GB/T 7714:Sheet metal forming: fundamentals[M]. Asm International, 2012.

MLA:Altan, Taylan, and A. Erman Tekkaya, eds. Sheet metal forming: fundamentals. Asm International, 2012.

APA:Altan, T., & Tekkaya, A. E. (Eds.). (2012). Sheet metal forming: fundamentals. Asm International.