Tooling Wear Reduction in Wall Sheet Forming

writer:优化 release time:2025-10-01 16:58:50 Views:73frequency

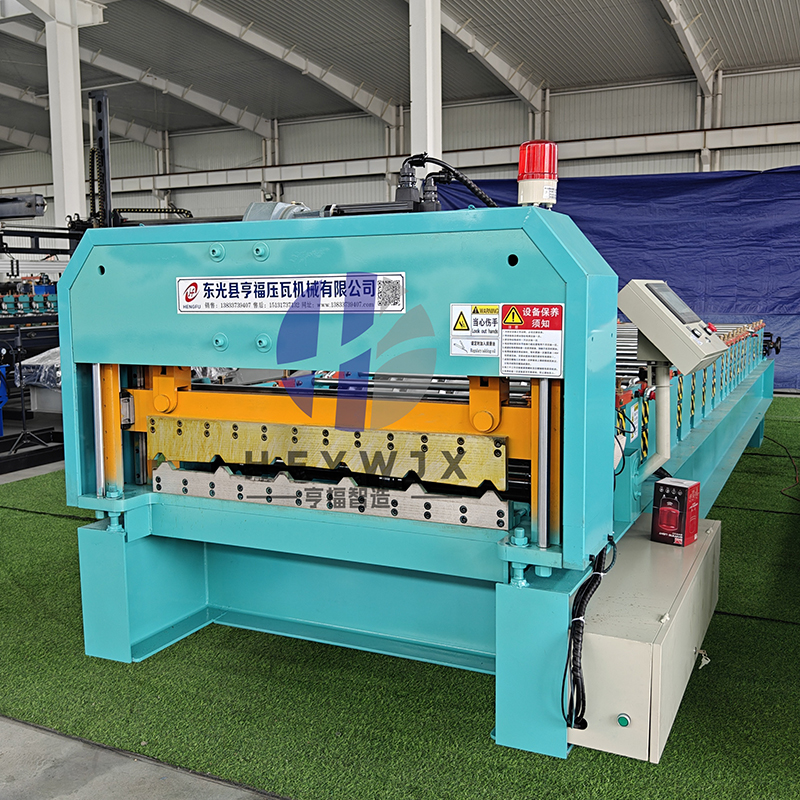

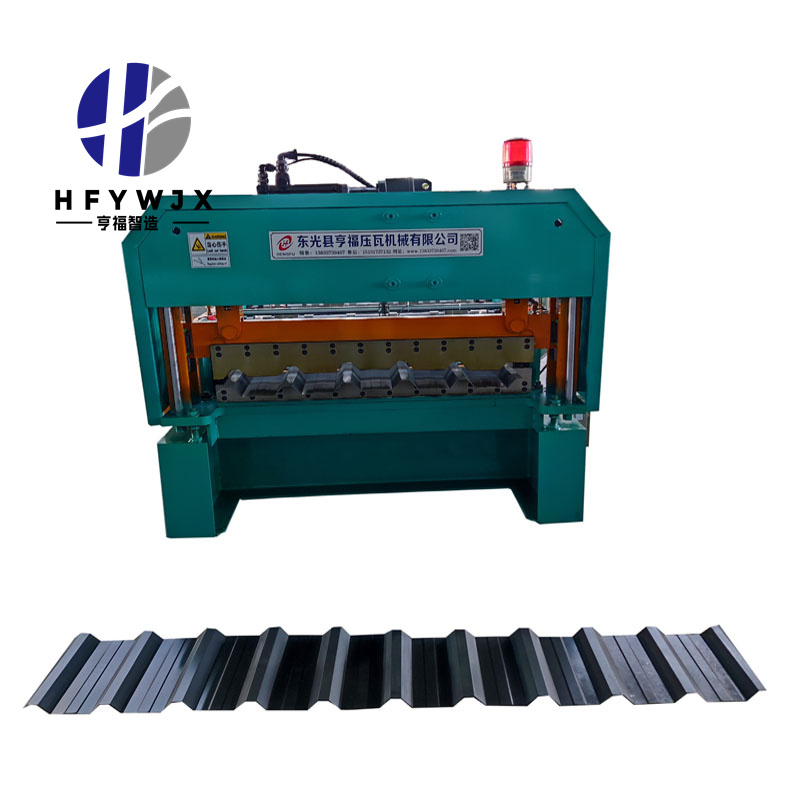

The wall sheet roll forming machine is central to modern construction material production, shaping coils of steel or aluminum into panels used for walls, cladding, and industrial buildings. One persistent challenge in roll forming operations is tooling wear. As rollers and dies gradually degrade, companies face higher costs, quality issues, and production delays.

This guide explores the root causes of tooling wear, practical methods to limit it, and the benefits of working with China manufacturers who can prove their bulk supply capabilities.

The Importance of Managing Tooling Wear

Every wall sheet roll forming machine depends on precision tooling. Rollers and dies must retain their shape and hardness to form consistent wall sheets. Over time, tooling degradation results in:

·Distorted sheet profiles and poor panel quality.

·Scratches and dents on finished products.

·Greater scrap generation and wasted material.

·Increased downtime due to frequent tool changes.

Without proactive strategies, these problems quickly escalate into costly production setbacks.

Main Causes of Tooling Wear

1.Material Hardness – Coils made of strong alloys increase stress on forming rolls.

2.Operational Speed – High-speed runs generate excessive heat and accelerate wear.

3.Lubrication Gaps – Insufficient lubrication leads to direct metal contact.

4.Alignment Issues – Even slight misalignment causes uneven pressure on tooling.

5.Poor Coil Quality – Impurities, burrs, or surface defects in coils damage tools prematurely.

Proven Ways to Reduce Tooling Wear

1. Upgrade to High-Strength Tooling

Carbide or hardened tool steel rollers resist abrasion and last longer, reducing replacement frequency.

2. Consistent Lubrication

Automated lubrication systems ensure friction and heat remain controlled during long production runs.

3. Alignment and Calibration

Routine inspection and alignment checks prevent uneven loads that shorten tooling life.

4. Balanced Production Speeds

Running at controlled speeds minimizes heat buildup while maintaining acceptable throughput.

5. Coil Material Selection

Partnering with trusted suppliers to source clean, burr-free coils prevents unnecessary tool damage.

Advantages of Reducing Tooling Wear

Optimizing a wall sheet roll forming machine to limit wear offers:

·Lower Costs: Reduced tooling replacements and repair expenses.

·Higher Output: Fewer stoppages and smoother production cycles.

·Better Quality: Consistently accurate wall sheets with clean finishes.

·Extended Lifespan: Protecting rollers preserves the machine’s long-term performance.

Broader Use Cases of Wall Sheets

The products from roll forming machines extend beyond industrial facades. They are widely used in:

·Commercial roofing and cladding systems.

·Agricultural warehouses and storage solutions.

·Prefabricated structures.

·Partition walls and modular building projects.

Because of this diversity, maintaining tooling integrity directly supports a wide range of industries.

Why Source from China Manufacturers?

Sourcing from China suppliers gives international buyers key advantages. Many reputable China manufacturers operate with bulk supply capacity, showing they are genuine producers with strong manufacturing infrastructure.

This guarantees:

·Stable product quality even for large-scale orders.

·Cost savings supported by mass production.

·Ongoing access to spare parts and technical support.

Working with such suppliers ensures that wall sheet forming operations remain both economical and reliable.

Conclusion

Reducing tooling wear is critical to maximizing the performance of every wall sheet roll forming machine. Through smart choices in material, lubrication, speed, and alignment, businesses can improve production quality and reduce downtime.

At the same time, sourcing from China manufacturers with verifiable bulk supply capabilities delivers both affordability and assurance of true manufacturing strength. For long-term success in wall sheet production, combining technical improvements with reliable sourcing is the best strategy.

References

GB/T 7714:Trzepieciński T. Approaches for preventing tool wear in sheet metal forming processes[J]. Machines, 2023, 11(6): 616.

MLA:Trzepieciński, Tomasz. "Approaches for preventing tool wear in sheet metal forming processes." Machines 11.6 (2023): 616.

APA:Trzepieciński, T. (2023). Approaches for preventing tool wear in sheet metal forming processes. Machines, 11(6), 616.