Vibration Reduction in Wall Sheet Forming Lines: Design & Maintenance

writer:优化 release time:2025-11-16 20:32:42 Views:161frequency

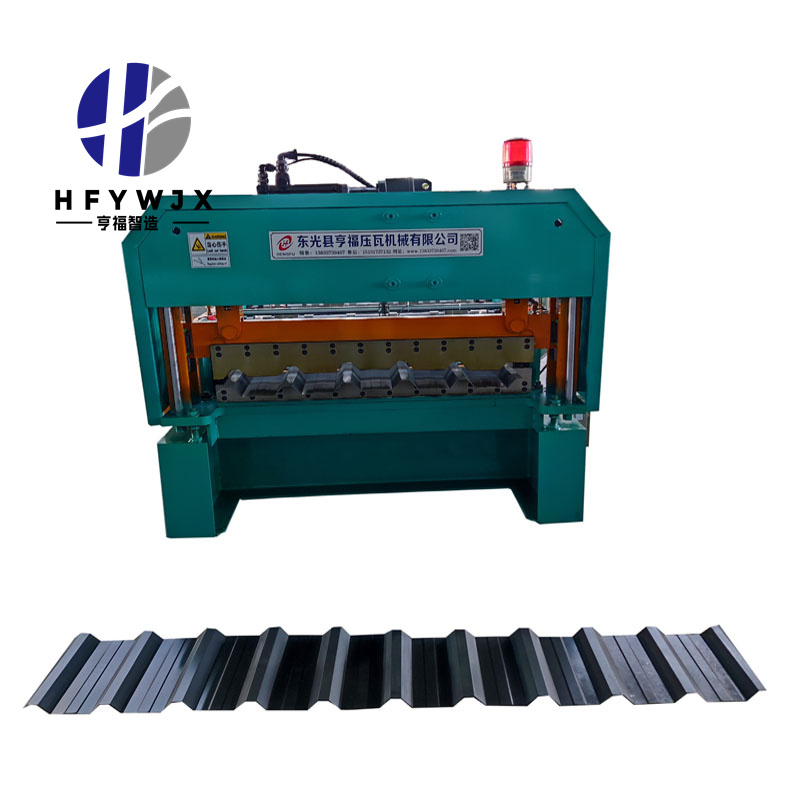

Consistent forming accuracy is critical in any Wall Sheet Roll Forming Machine, especially when a production line operates for long hours or processes a wide range of sheet thicknesses. One of the biggest obstacles to achieving consistent quality is vibration. Even minor vibration can gradually influence panel straightness, forming angles, and surface finish. For manufacturers running bulk Production of wall panels, minimizing vibration is essential to ensure efficiency, reduce scrap, and extend equipment lifetime.

This deep guide examines how vibration forms inside a roll forming line, how thoughtful machine design reduces oscillation, and what maintenance steps help stabilize long-term operation.

1. Understanding What Causes Vibration in Wall Sheet Roll Forming Systems

Vibration is a natural result of mechanical motion, but in a forming line, it becomes problematic when it impacts shaping accuracy or damages machine components. Several mechanical and material-based factors commonly trigger excessive vibration:

• Rotational imbalance in rollers or shafts

Uneven roller surfaces or weight distribution causes continuous oscillation during high-speed rotation.

• Poor alignment between stands

If forming stands are not aligned along a straight reference axis, the sheet is forced to bend sideways, creating lateral vibration.

• Transmission wear

Stretched chains, misaligned couplings, and worn gears transfer irregular motion directly into the forming path.

• Coil variability

Wall sheet coils with inconsistent thickness or stiffness create fluctuations in forming pressure, increasing vibration levels.

• Structural flexibility

A weak or lightly built machine frame transmits vibration instead of dampening it.

Recognizing these sources helps operators troubleshoot vibration before major panel defects appear.

2. Structural Design Features That Reduce Vibration

A high-quality Wall Sheet Roll Forming Machine is engineered to resist vibration at its core. When evaluating or designing equipment, the following structural features significantly influence stability:

✔ Heavily reinforced base frame

A thicker, welded-steel frame absorbs the impact of moving components, ensuring the machine remains stable even under heavy workloads.

✔ Precision-machined rollers and shafts

Well-balanced rollers reduce rotational oscillation, improving smoothing during panel shaping.

✔ Torsion-resistant support stands

Rigid stands prevent vertical or horizontal shifting that could distort forming angles.

✔ Adjustable alignment mechanisms

Fine-tuning screws or dial alignment systems enable operators to correct stand alignment quickly.

✔ Floor anchoring and anti-vibration pads

Secure anchoring prevents movement over time, while isolating pads dampen resonance.

Machines built with these design principles experience significantly lower vibration—even during high-speed production cycles.

3. The Role of Proper Installation in Minimizing Vibration

Even a perfectly designed machine will vibrate if installed incorrectly. Installation errors are one of the most common causes of oscillation in newly built production lines.

• Level every forming station

Use precision leveling tools to prevent one side of the machine from loading more than the other.

• Anchor the line firmly to the ground

Loose or insufficient anchoring allows the machine to shift gradually under load, increasing vibration over time.

• Align roller stands along a single reference plane

Ensures that the sheet moves forward without side-loading forces.

• Check drive chain tightness during setup

Chains that are too loose cause jerky movement, while those too tight generate unnecessary stress.

• Verify proper roller clearance

Uniform roller gaps ensure stable pressure distribution and prevent bouncing or noise.

A high-quality installation ensures long-term stability and reduces maintenance needs.

4. Optimizing Line Operation to Keep Vibration Under Control

Once the line is running, operators still influence vibration levels through daily decisions and operating habits.

1. Adjust production speed appropriately

Faster isn’t always better—over-speeding amplifies vibration, especially when forming thick wall sheets.

2. Maintain consistent feeding tension

Uneven feeding tension leads to sudden shifts in roller pressure.

3. Apply proper lubrication

Lubricating bearings, chains, and shafts reduces friction, balancing rotation and lowering vibration.

4. Monitor roller temperature

High heat expands roller surfaces, disrupting clearance and alignment.

5. Use high-quality coils

Wavy, dented, or inconsistently thick coils introduce unpredictable vibration into the forming cycle.

Operational awareness is one of the simplest yet most effective vibration control strategies.

5. Maintenance Practices That Prevent Vibration Buildup

Continuous Production lines endure heavy wear. Without routine maintenance, even minor wear can escalate into significant vibration.

✔ Clean and inspect rollers regularly

Built-up residue or tiny dents lead to irregular rotation.

✔ Replace worn bearings immediately

Bearings play a major role in vibration damping; worn bearings increase noise and stress.

✔ Lubricate chains, gears, and shafts consistently

Proper lubrication keeps transmission smooth.

✔ Check the gearbox for wear and backlash

A noisy gearbox often indicates misalignment that can spread vibration through the entire system.

✔ Tighten structural bolts and check frame stability

Loose bolts increase machine resonance during forming.

Preventive maintenance dramatically reduces long-term repair costs and improves forming precision.

6. The Impact of Vibration on Final Wall Sheet Quality

Uncontrolled vibration affects wall sheet appearance and structural performance, leading to:

·Uneven rib heights

·Twisted or wavy panels

·Surface lines or abrasion marks

·Inconsistent sheet thickness

·Dimensional inaccuracy

These flaws can significantly increase scrap rates, disrupt project schedules, and affect customer satisfaction. For manufacturers supplying large-volume panel orders, vibration control is essential to maintain professional output standards.

Conclusion: Stable Production Begins with Controlled Vibration

A reliable Wall Sheet Roll Forming Machine must operate smoothly, with minimal vibration, to deliver consistent panel shape and surface quality. By understanding vibration sources, designing rigid machine structures, installing lines correctly, adopting stable operating procedures, and maintaining equipment regularly, manufacturers can reduce defect rates and enhance long-term performance. For any Manufacturer providing bulk forming-line Production, vibration control is not just good practice—it is a competitive advantage.

References

GB/T 7714:Schmitz T L, Smith K S. Mechanical vibrations[M]. Springer US, 2012.

MLA:Schmitz, Tony L., and K. Scott Smith. Mechanical vibrations. Springer US, 2012.

APA:Schmitz, T. L., & Smith, K. S. (2012). Mechanical vibrations. Springer US.