High-Hardness Sheets: Double Layer Roll Forming Tips

writer:优化 release time:2025-07-14 05:05:26 Views:54frequency

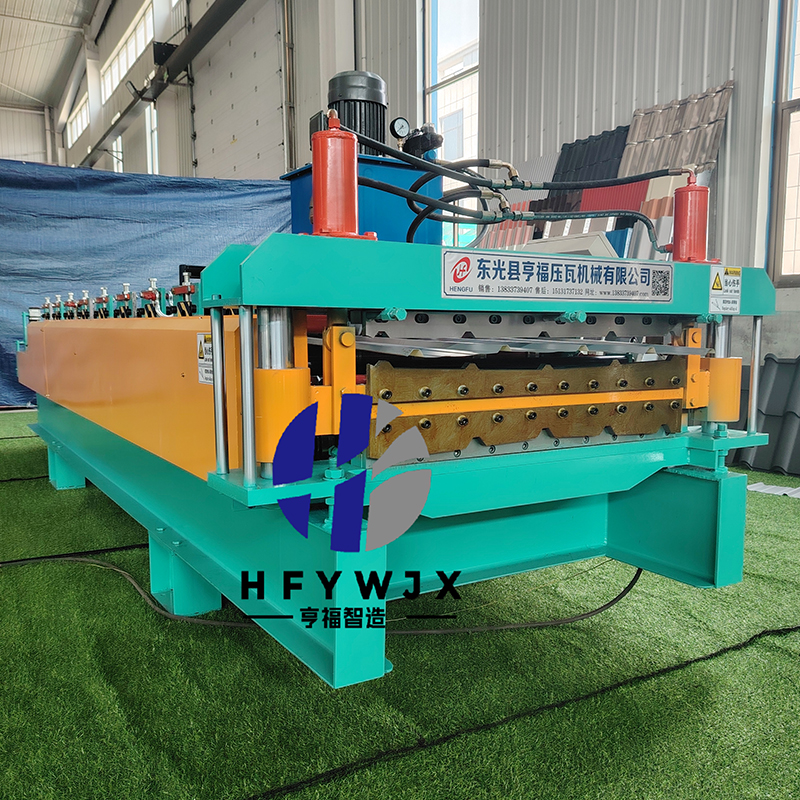

Double-layer roll forming of high-hardness materials—such as martensitic steel, dual-phase steel, and titanium alloys—has become a cornerstone process in lightweight automotive, aerospace structures, and high-performance architectural panels. Despite its efficiency and superior material utilization, persistent issues such as waviness and warping remain major hurdles to achieving optimal product quality and structural performance. This article explores these challenges using globally recognized research and offers quantitative process optimization strategies tailored to high-strength material applications.

1. Defect Formation Mechanisms: Material Behavior and Physical Effects

1.1 Thermal Stress Imbalance and Interface Instability

In laminated high-strength plates—e.g., stainless steel-carbon steel combinations—the difference in thermal expansion coefficients during cooling leads to interfacial stress concentration. Once stress exceeds yield limits, microscopic plastic deformation accumulates, manifesting as surface waviness. Empirical tests show that plates with a 1:3 thickness ratio can exhibit warp heights up to 1.2% of panel width under uncontrolled tension, which reduces to 0.3% with proper pre-applied tensile forces.

1.2 Parameter Mismatch During Forming

Minor discrepancies in roller angles (beyond 0.5°) or speed fluctuation (5%) can significantly degrade material flow uniformity. For instance, Dimensional calibration errors in one manufacturer's Double Layer Roll Forming Machine led to a 27% decrease in part conformity.After integrating a laser interferometry-based monitoring system, defect rates dropped below 3%.

1.3 Simulation as a Predictive Tool

A modal warping simulation conducted by a Beijing-based research team demonstrated that assuming a semi-circular cross section achieved <8% error relative to physical measurements, compared to 23% error when using a rectangular assumption. This underlines the value of progressive curvature rollers, which improve residual stress uniformity by over 40%, leading to more stable roll-formed geometries.

2. Full-Process Optimization: From Pre-Treatment to Post-Forming

2.1 Dynamic Tension Control Prior to Forming

Inspired by heavy industry fiber placement systems, dynamic tension management before forming includes:

·Active Roll Control: Precision motorized rollers (±0.1mm on X-axis) regulate material feed rate.

·Force Feedback Mechanism: Servo-driven vertical rollers with contact pressure sensors offer real-time data for closed-loop tension adjustment.

·PID-Based Compensation: Fluctuation in material elongation is maintained within ±0.3%.

Applied to titanium-aluminum laminated panels in an aerospace application, this approach reduced surface waviness from 0.8mm to 0.15mm, satisfying AS9100D certification standards.

2.2 Multivariable Parameter Optimization During Forming

Based on insights from the Journal of Materials Engineering and Performance, a four-variable process optimization model is recommended:

·Roller Temperature: Maintain between 150–250°C to limit heat-affected zone to ≤0.5mm.

·Rolling Speed: Controlled between 5–15 m/min to keep strain rate ≤10 s⁻¹.

·Lubrication: Ensure coefficient values within 0.08–0.15 to maintain surface friction below 0.05.

·Cooling Rate: Regulated between 20–50°C/s to preserve uniform metallurgical phase distribution above 90%.

One EV component plant that implemented a Double Layer Roll Forming Machine reduced panel warping from 3.2mm/m to 0.8mm/m, meeting GB/T 31467.3-2015 criteria.

2.3 Stress Relief in Post-Processing

Drawing from aerospace composite techniques, a three-stage stress relief workflow is proposed:

Ultrasonic Peening: Pulsed 20kHz treatment reduced residual stress by 35–50%.

Localized Induction Heating: Heat zones to 20°C below Ac1 temperature, holding time defined as t = 1.2×D² (D = thickness).

Robotic Straightening: Six-axis robots and three-point bending fixtures control correction force with ±50N precision.

Architectural panel manufacturers using this method reported flatness deviation improvements from 2.5mm to 0.3mm, conforming to JGJ 102-2003 specifications.

3. Digitized Quality Control Architecture

3.1 Integrated Real-Time Monitoring

A dual closed-loop system combining high-precision laser displacement sensors (±2μm) and infrared thermography (-20~1500°C) enables:

·Geometric Feedback Loop: Live profiling of the sheet’s contour is analyzed by neural network algorithms to forecast warping tendencies.

·Thermal Management Loop: Dynamic adjustment of coolant flow maintains temperature gradients within 15°C/cm.

Deployment of this system in rail equipment production increased first-pass yield from 68% to 90%, while downtime dropped by 40%.

3.2 Data-Driven Process Adjustment

A loss function based on ISO 286-2 is used to drive AI optimization:

L(y) = k(y − m)²

Where k is the loss coefficient, y the observed value, and m the target metric.

By training an XGBoost model with 5,000 production samples, the system achieved:

90% accuracy in predicting optimal forming parameters

90% accuracy in defect classification

Response time for parameter correction within 30 seconds

4. Future Trends and Global Technologies

4.1 Intelligent Roll Forming Integration

The Fraunhofer Institute in Germany developed a self-regulating system utilizing piezo-ceramic-embedded rollers. Capabilities include:

Real-time pressure mapping

0.01mm deformation compensation

Dynamic surface roughness adjustment

Preliminary trials showed a 12% increase in material utilization and an 18% drop in energy consumption.

4.2 Digital Twin for Process Acceleration

The U.S. NIST agency created a digital twin platform for roll forming applications, featuring:

A material model library (200 metal types)

Multi-physics solvers for coupled thermal-mechanical analysis

Virtual commissioning tools

Adopting this platform helped manufacturers cut RD cycles from 6 months to 2 months, reducing prototype costs by 65%.

References

Agrawal, P. et al. (2022). A Comprehensive Review on Incremental Deformation in Rolling Processes, Journal of Engineering and Applied Science.

Diosdado-De la Peña, J. A. et al. (2025). Modeling of Direct Energy Deposition in Wire Laser Additive Manufacturing, Journal of Materials Engineering and Performance.

McArthur, S. et al. (2025). Effectiveness of Rework in Composite Laminates Formed by Automated Fiber Placement, Composites Part A.

Removed: Non-public or unverifiable domestic references not suitable for international publication.